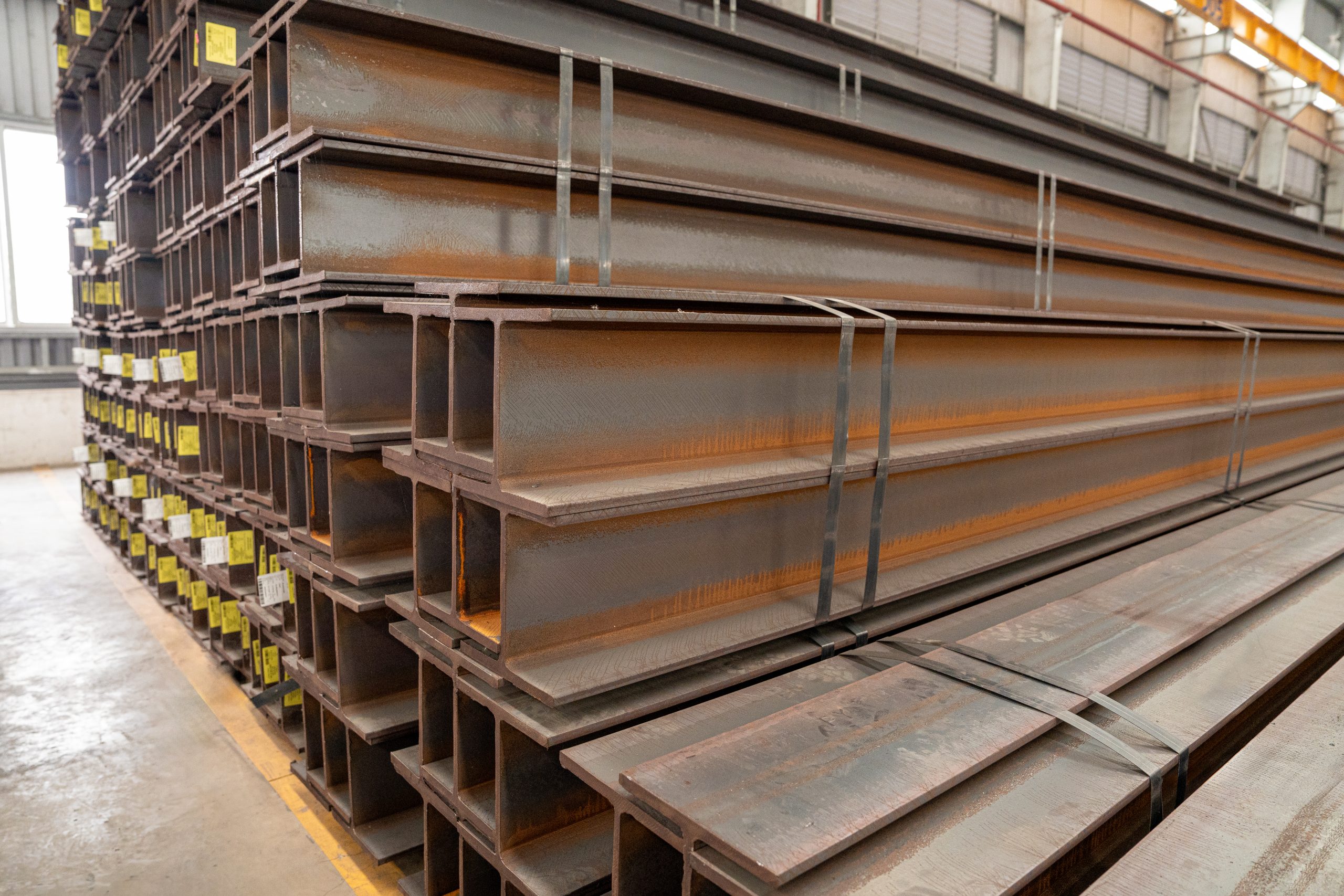

H Beam

H Beam

Size range:

H100 - H900

Thickness:

06 - 40mm

Length:

6,000 / 12,000mm or cut-to-size

Grades:

S400, A36, A572, S355JR, SM490, etc

Mills:

Posco Yamato Vina, JFE Steel, Nippon Steel, Huyndai Steel, Thai Nguyen (Tisco), etc

Production standards:

JIS G3101:2015, ASTM, EN 10025-2:2019, JIS G 3106:201, etc

Key advantages:

- Exceptional load-bearing capacity for heavy structures

- Material and cost efficiency through optimized material design

- Easy of assembly with standardized connections

- Superior stability under dynamic loads

- Flexible application, multi-purpose solution for all projects

- Diverse in size and steel grade

High production output

Large manufacturing capacity to efficiently fulfill bulk orders and key projects.

Competitive pricing

Offering budget-friendly yet competitive prices while maintaining product quality.

Trusted by clients

Chosen by hundreds of domestic and international clients for consistent quality and professional service.

Describe Product

Mục lục

H-beam is an ideal construction material renowned for its superior load-bearing capacity, thanks to its wide-flange and thick-web design. This product offers cost efficiency, easy installation, and excellent structural stability for industrial workshops, bridges, and high-rise buildings. Compliant with JIS, ASTM, and GB standards, H-beam is perfect for projects demanding durability and reliability.

I. FEATURES

- High load-bearing capacity: With wide flanges and an optimized cross-sectional design, H-beam steel distributes loads more efficiently and provides exceptional structural strength.

- Cost-effective construction: The shape ensures uniform stress distribution, reduces unnecessary weight while maintaining rigidity, resulting in lower overall construction costs.

- Ease of fabrication and assembly: Straight edges and uniform dimensions make H-beams easy to cut, weld, bolt, and assemble on-site, saving both time and labor costs.

- Superior stability

- Versatile applications: Thanks to its high flexibility, H-beam steel is widely used in civil and industrial construction, bridges, factories, shipbuilding, and other heavy-load structures.

- Various sizes and steel grades: Manufactured to international standards (ASTM, JIS, EN, etc.), H-beams are available in a wide range of sizes and steel grades to meet diverse project requirements.

| Tính chất vật lý(Mechanical Properties) | Tính chất hoá học(Chemical Composition) | |||||||

|---|---|---|---|---|---|---|---|---|

| Mác thép(Grade) | Độ bền chảy(Yeild Strength) (Mpa ~ N/mm2) Min |

Độ bền kéo(Tensile Strength) (Mpa ~ N/mm2) Min |

Độ giãn dài(Elongation) % |

C% | Si% | Mn% | P% | S% |

| SS400 | ≥ 245* | 400 – 510 | ≥ 21 | ≤ 0.29 | ≤ 0.40 | ≤ 1.6 | ≤ 0.050 | ≤ 0.050 |

| A36 | ≥ 250 | 400 – 550 | ≥ 20 | ≤ 0.26 | ≤ 0.40 | ≤ 0.040 | ≤ 0.050 | |

| A572 Gr50 | ≥ 345* | 450 – 620 | ≥ 18 | ≤ 0.23 | 0.15 – 0.40 | 1.35 – 1.65 | ≤ 0.040 | ≤ 0.050 |

| S355JR | ≥ 355 | 470 – 630 | ≥ 20 | ≤ 0.22 | ≤ 0.55 | ≤ 1.6 | ≤ 0.035 | ≤ 0.035 |

| SM490 | ≥ 325 | 490 – 610 | ≥ 19 | ≤ 0.20* | ≤ 0.55 | ≤ 1.6 | ≤ 0.035* | ≤ 0.035* |

II. TOLERANCE

Thickness tolerance: 0.7mm – 1.7mm

Weight tolerance: ± 3– 5%

Wing tolerance: 0.2mm – 0.4mm

Length tolerance: 40mm – 65mm

IIi. PACKING AND DELIVERY

Bundle weight: 3.0 – 3.5 tons per bundle

IV. PRACTICAL APPLICATIONS

- Industrial construction & pre-engineered buildings: H-beams are used as columns, beams, and main trusses in steel frame structures, offering high load-bearing capacity and fast installation. Additionally, H-beams serve as the main framework for large-span buildings, reducing the number of columns and increasing usable space.

- Bridges, roads and infrastructure: Used as main and edge girders due to their excellent bending resistance and long-term durability. Also applied in temporary bracing, retaining walls, and ground/foundation reinforcement (both temporary and permanent).

- Mechanical engineering & machinery: Used to build machine frames, equipment supports, cranes, conveyors, and operator platforms.

- Transportation sector: H-beams are used in primary load-bearing frames to ensure structural stability during movement. Also used in the construction of bus stops, weigh stations, and covered terminals.

- Shipbuilding and oil & gas industry: Utilized in the structural framework of ships and large transport vessels. Also used in offshore oil rigs and port infrastructure.

V. H-BEAM BRANDS

Currently, there are several well-known and reputable H-beam steel brands on the market, including: Posco Yamato Vina, Thai Nguyen (Tisco), Huyndai Steel, Siam Yamato Steel, etc

Angle Steel

Angle Steel U Beam

U Beam H Beam

H Beam I-BEAM

I-BEAM Steel Plate

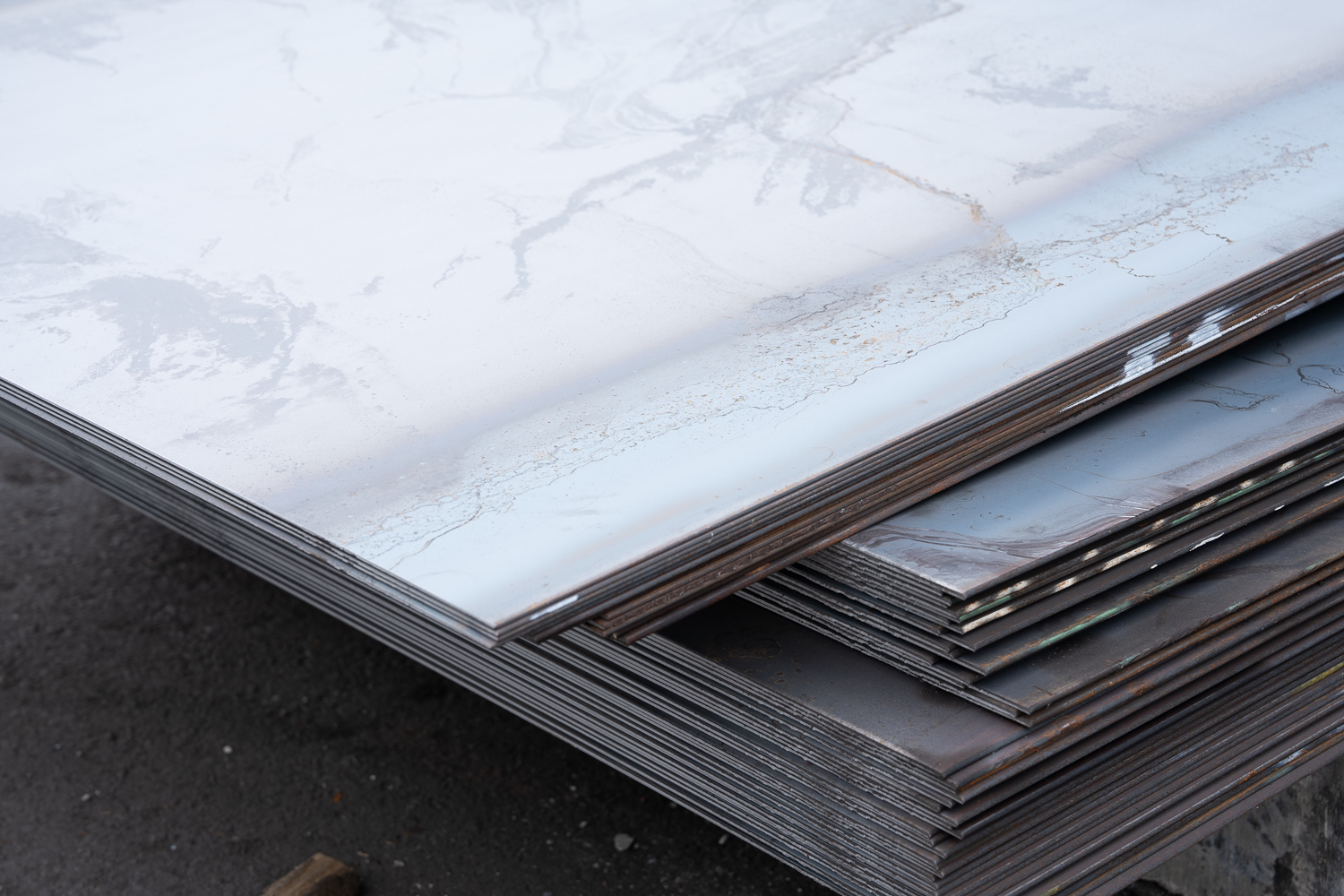

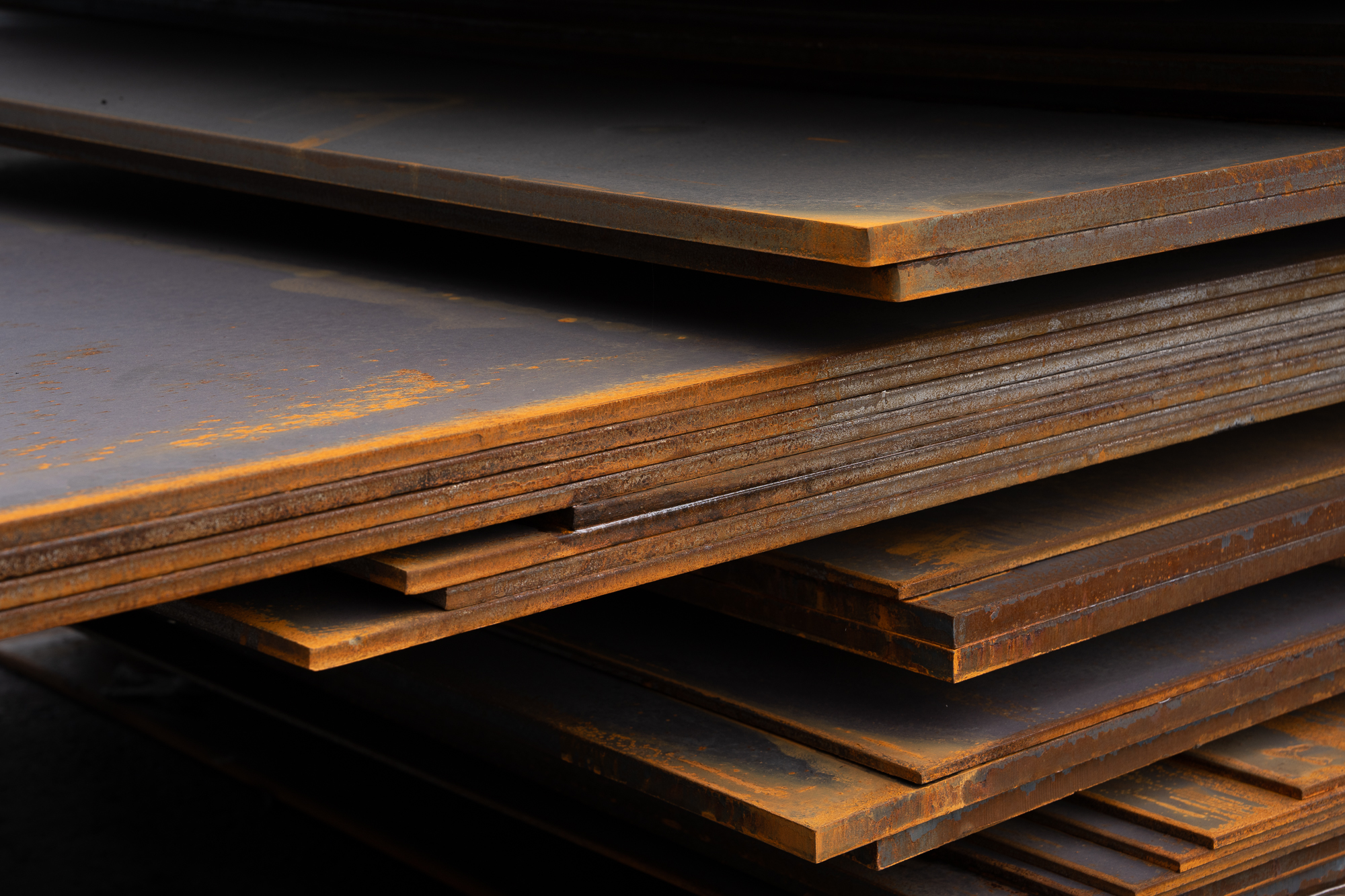

Steel Plate Steel Sheet

Steel Sheet High Strength Steel Plate

High Strength Steel Plate Special Steel Plate

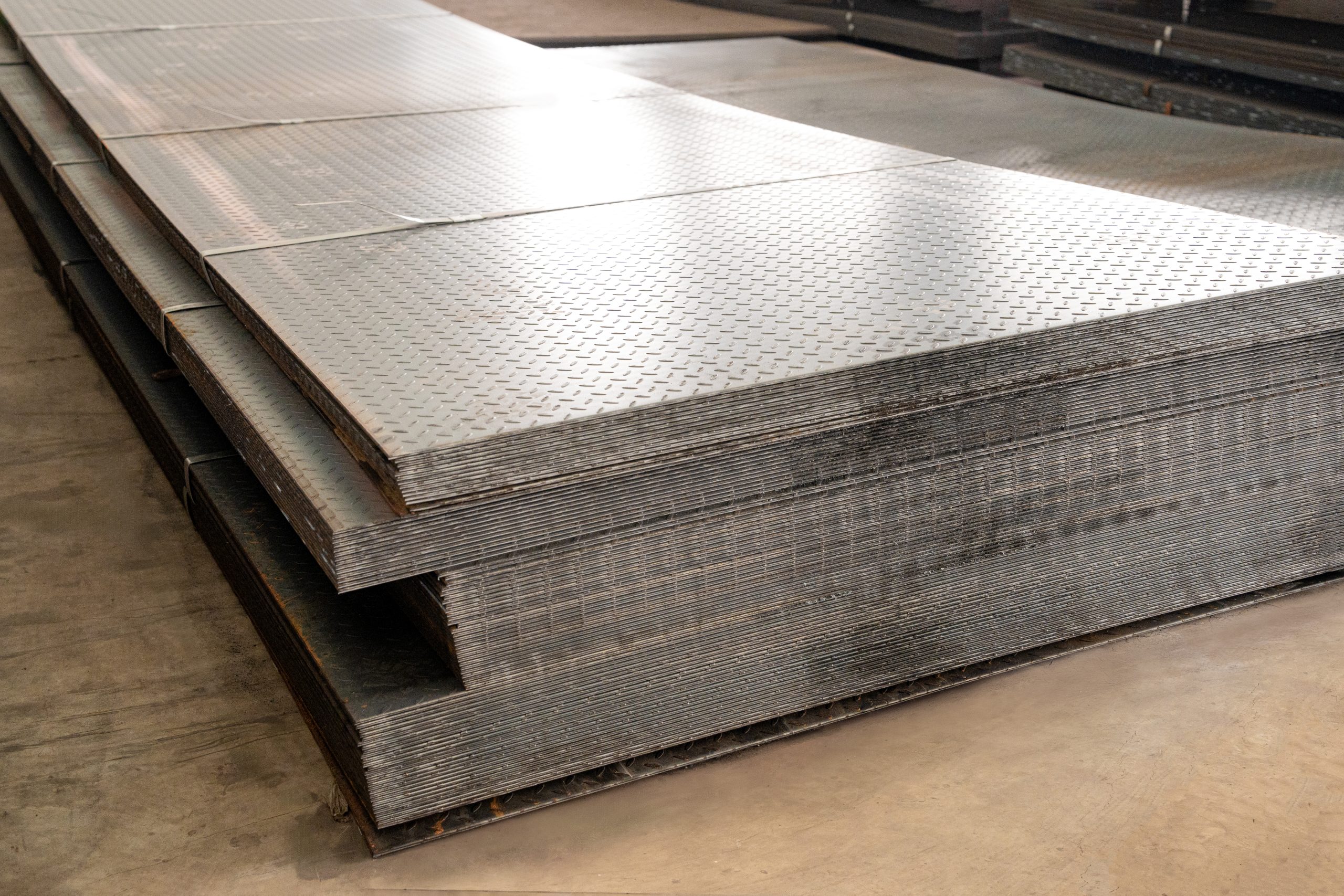

Special Steel Plate Checkered Steel Plate

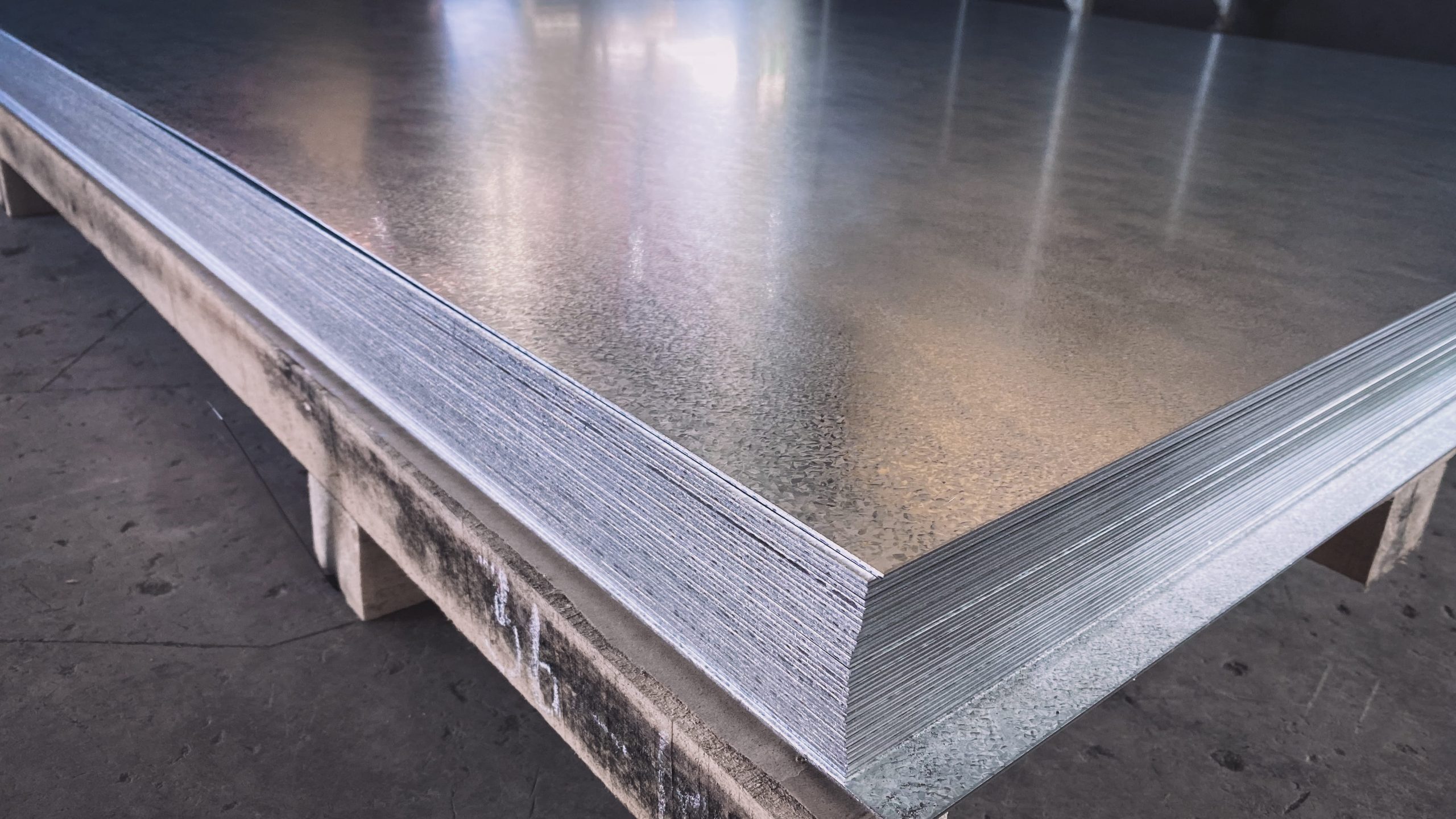

Checkered Steel Plate Galvanized Steel Sheet

Galvanized Steel Sheet Hot Rolled Coil

Hot Rolled Coil Cold Rolled Coil

Cold Rolled Coil Galvanized Coil

Galvanized Coil Steel Strip

Steel Strip Square Bar

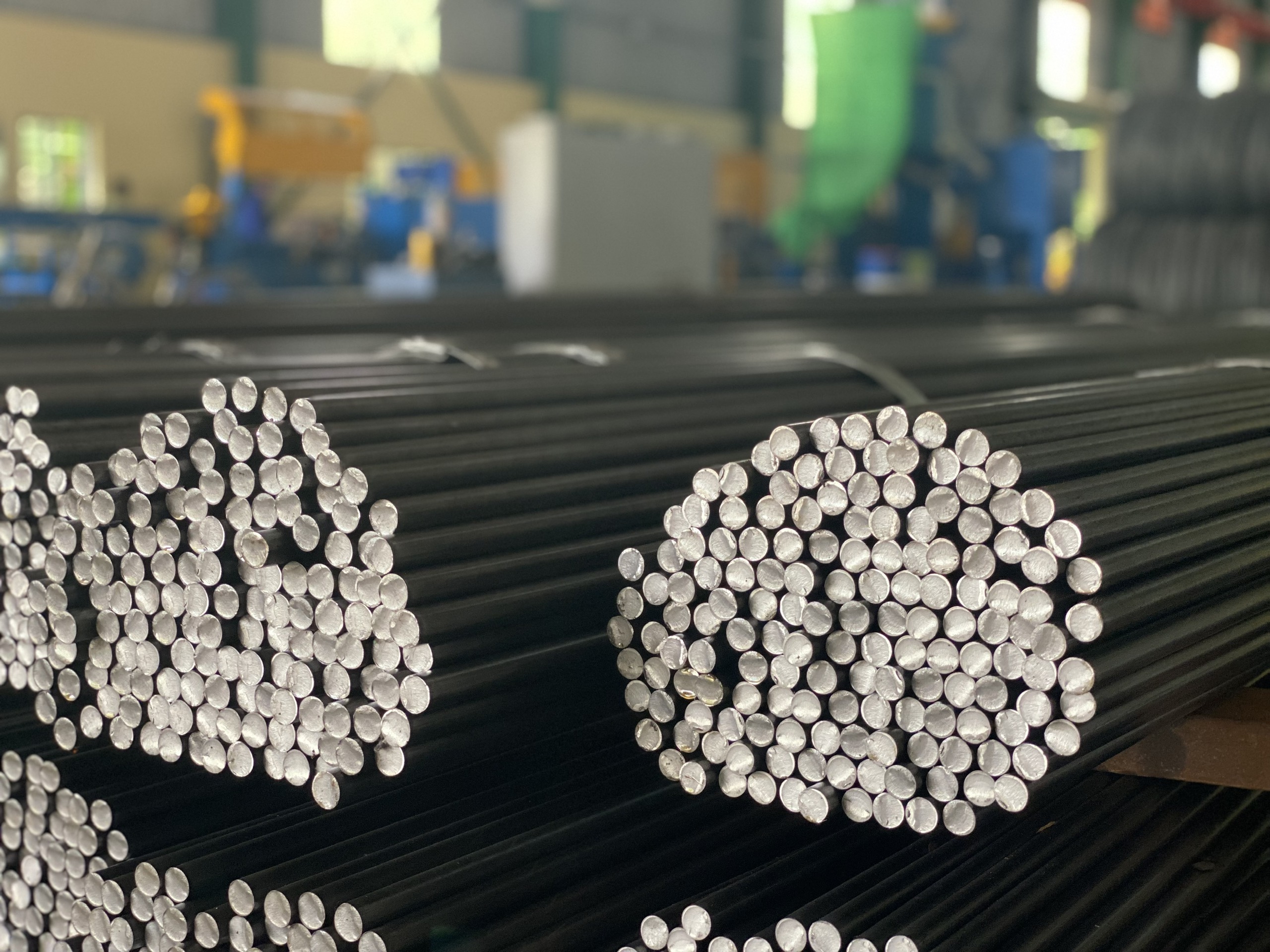

Square Bar Round Bar

Round Bar WELDED PIPE

WELDED PIPE Seamless Steel Pipe

Seamless Steel Pipe Steel tube

Steel tube Square Tube

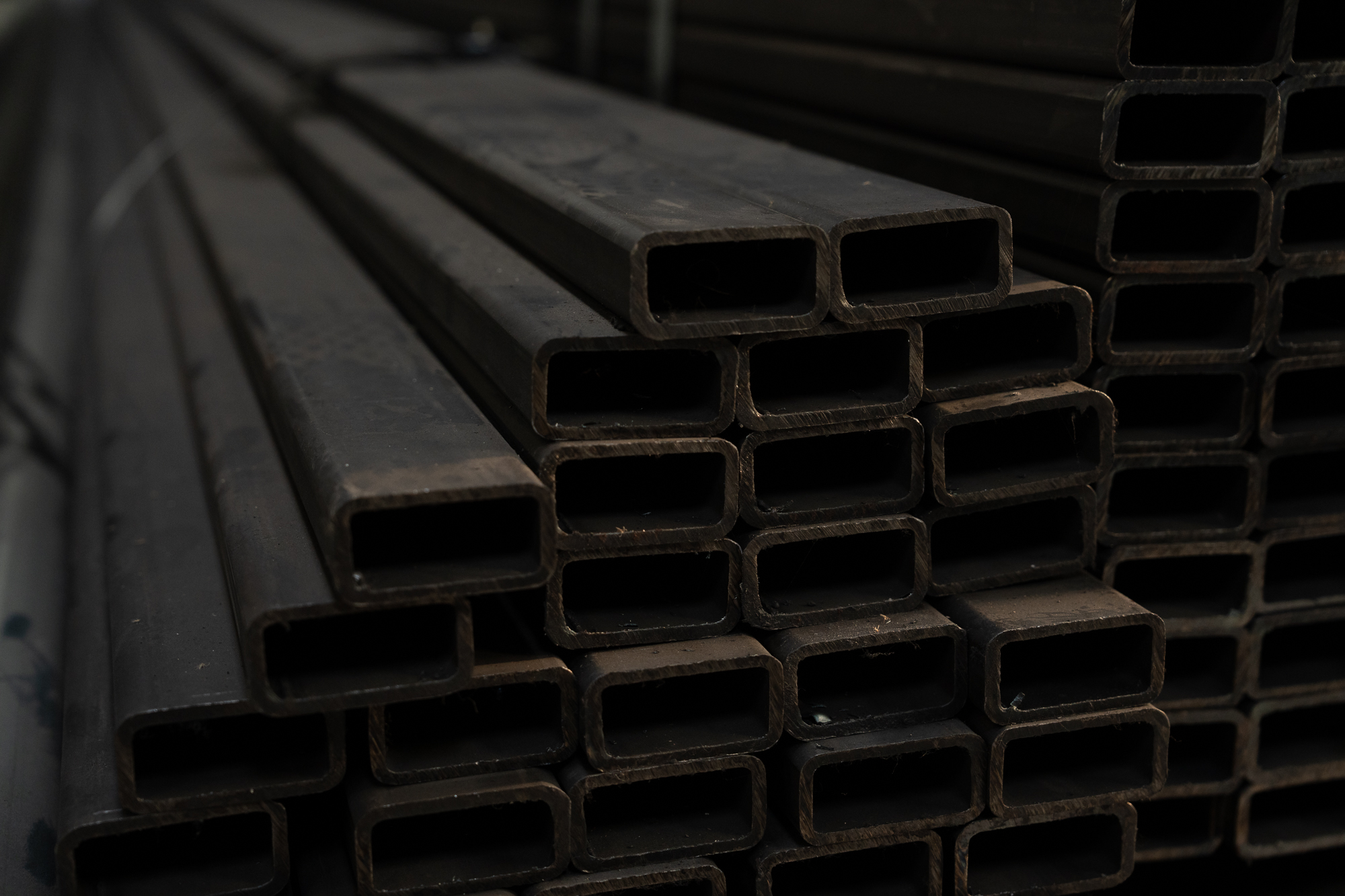

Square Tube Rectangular Tube

Rectangular Tube Wire Rod

Wire Rod Deformed Bar

Deformed Bar Steel Sheet Pile

Steel Sheet Pile Steel Purlin

Steel Purlin Steel Rail

Steel Rail Steel Fittings

Steel Fittings Stainless Steel

Stainless Steel Steel Fabrication

Steel Fabrication