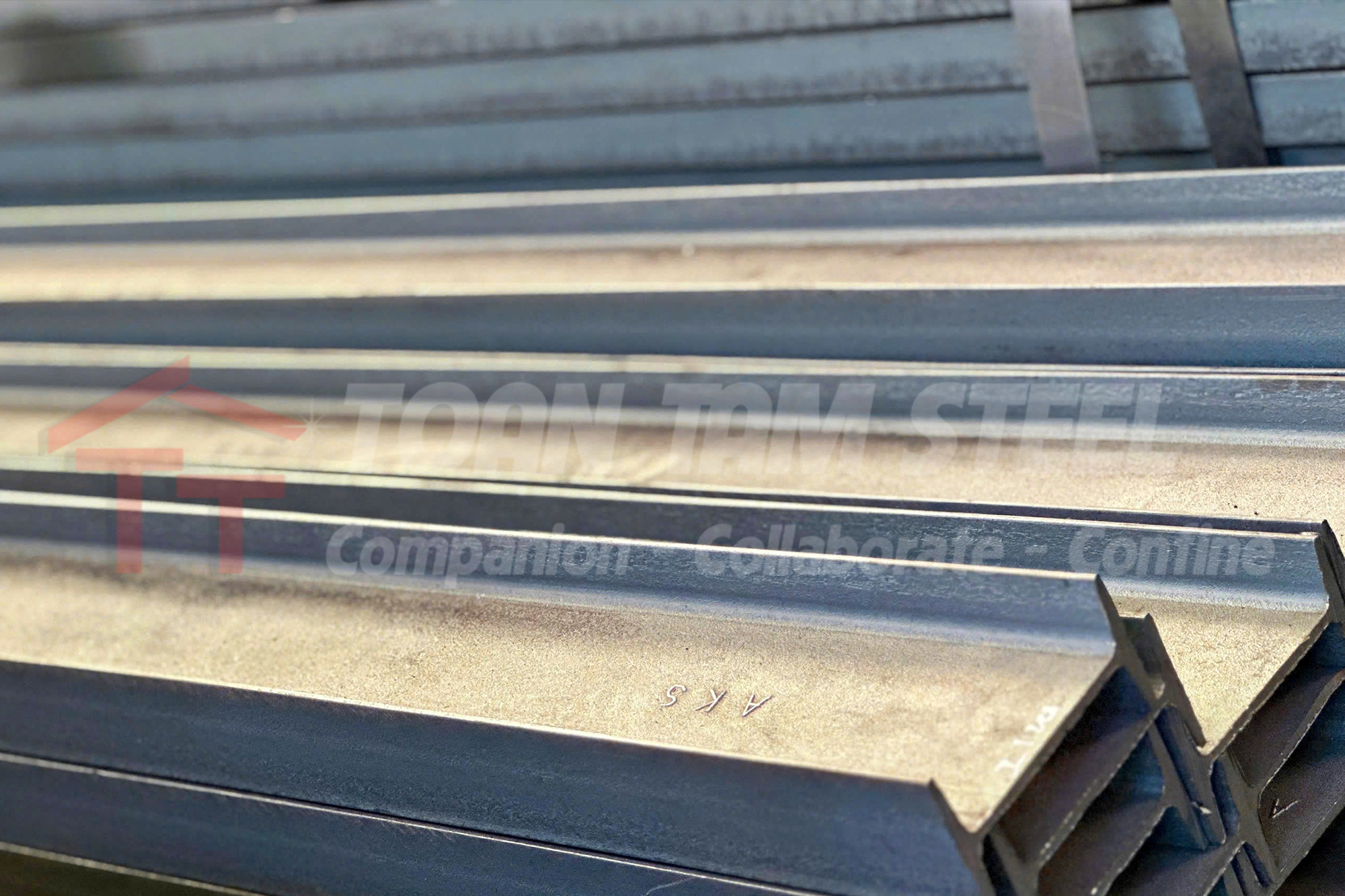

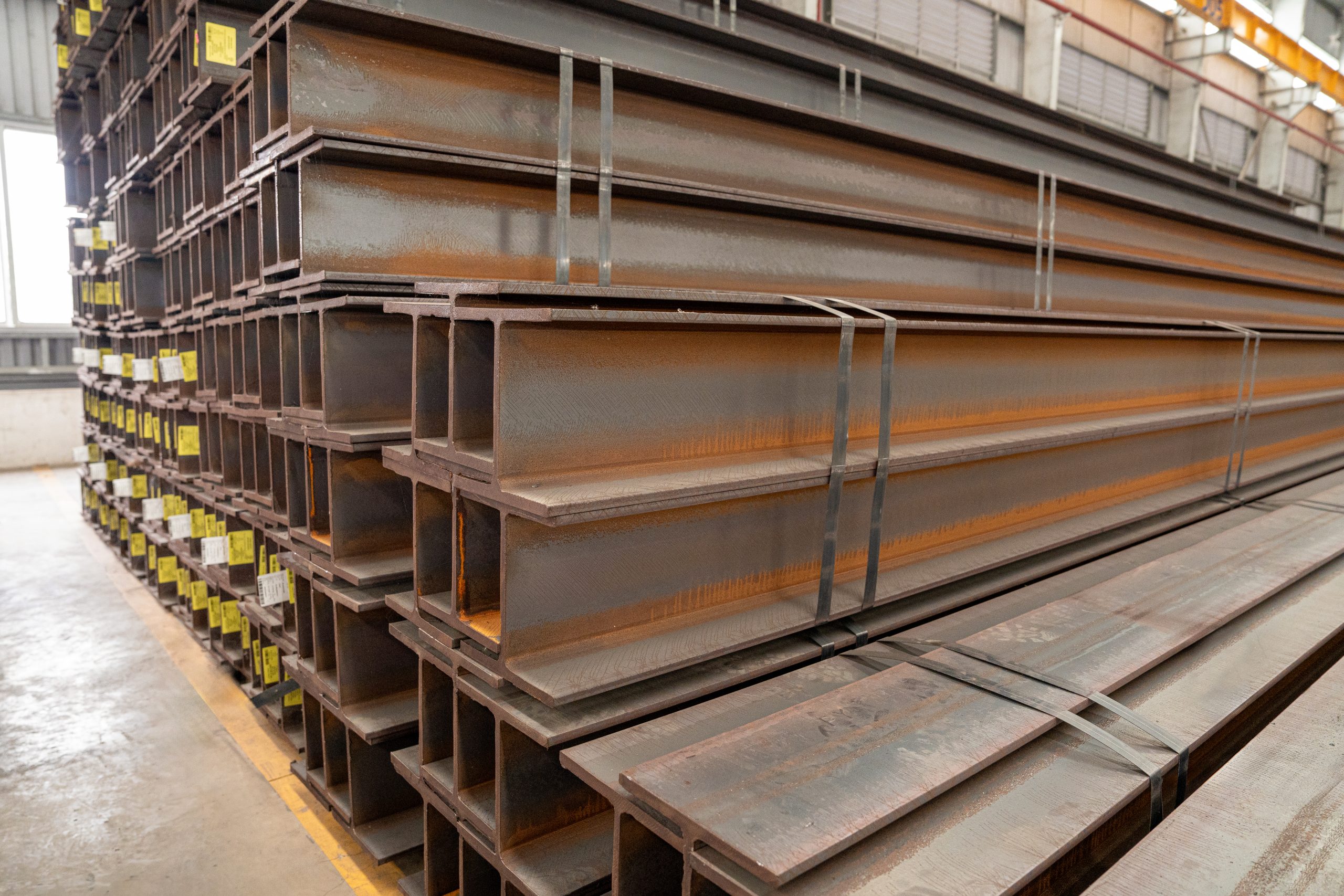

I-BEAM

I-BEAM

Size range:

I100 – I700

Flange & web thickness:

06 – 40mm

Length:

6,000 / 12,000mm or cut-to-size

Grades:

SS400, A36, A572, S355JR, SM490, etc

Mills:

Posco Yamato Vina, An Khanh Steel, Nippon Steel, Siam Yamato Steel, etc

Standards:

JIS G3101:2015, ASTM, EN 10025-2:2019, JIS G 3106:201, etc

Key advantages:

- Exceptional load-bearing capacity

- Economic efficiency in construction

- Easy fabrication and installation

- Versatile applications

- Superior stability and bending resistance

- Wide range of sizes and steel grades

High production output

Large manufacturing capacity to efficiently fulfill bulk orders and key projects.

Competitive pricing

Offering budget-friendly yet competitive prices while maintaining product quality.

Trusted by clients

Chosen by hundreds of domestic and international clients for consistent quality and professional service.

Describe Product

Mục lục

I-beam is a structural steel with an I-shaped cross-section, consisting of a vertical web connecting two horizontal flanges. Thanks to its optimized material distribution, I-beam delivers exceptional bending and compression resistance, achieving a high strength-to-weight ratio that reduces construction costs. Typically manufactured from carbon steel (SS400, A36) or low-alloy steel (A572 Gr.50, S355JR), it is widely used for factory support beams, bridge girders, high-rise building columns, and industrial machinery frames.

I. FEATURES

- Exceptional load-bearing capacity: With optimized force distribution (flanges resist bending, web resists shear), I-beams support extreme loads up to 500 tons over 30m spans, ideal for cranes and heavy factories.

- Economic efficiency in construction: Saves costs versus concrete through lightweight properties, reduced foundation materials, and rapid bolted modular assembly.

- Easy fabrication and installation: Optimal factory prefabrication (hole cutting, end-plate welding), and tool-free site assembly reduces labor cost and waste versus cast-in-place concrete.

- Versatile applications: Widely used in civil/industrial construction, bridges, plants, shipbuilding, and heavy-load structures due to unmatched versatility.

- Superior stability and bending resistance: The I-shape concentrates material at the flanges (maximum bending stress zones), creating higher moment of inertia, and limiting deflection.

- Wide range of sizes and steel grades: Manufactured to international standards (JIS, ASTM, EN, etc), I-beams are available in a wide range of sizes and steel grades to meet diverse project requirements.

| Tính chất vật lý(Mechanical Properties) | Tính chất hoá học(Chemical Composition) | |||||||

|---|---|---|---|---|---|---|---|---|

| Mác thép(Grade) | Độ bền chảy(Yeild Strength) (Mpa ~ N/mm2) Min |

Độ bền kéo(Tensile Strength) (Mpa ~ N/mm2) Min |

Độ giãn dài(Elongation) % |

C% | Si% | Mn% | P% | S% |

| SS400 | ≥ 245* | 400 – 510 | ≥ 21 | ≤ 0.29 | ≤ 0.40 | ≤ 1.6 | ≤ 0.050 | ≤ 0.050 |

| A36 | ≥ 250 | 400 – 550 | ≥ 20 | ≤ 0.26 | ≤ 0.40 | ≤ 0.040 | ≤ 0.050 | |

| A572 Gr50 | ≥ 345* | 450 – 620 | ≥ 18 | ≤ 0.23 | 0.15 – 0.40 | 1.35 – 1.65 | ≤ 0.040 | ≤ 0.050 |

| S355JR | ≥ 355 | 470 – 630 | ≥ 20 | ≤ 0.22 | ≤ 0.55 | ≤ 1.6 | ≤ 0.035 | ≤ 0.035 |

| SM490 | ≥ 325 | 490 – 610 | ≥ 19 | ≤ 0.20* | ≤ 0.55 | ≤ 1.6 | ≤ 0.035* | ≤ 0.035* |

II. TOLERANCE

Thickness tolerance: ±0.5 – 0.8mm

Flange & web length tolerance: ±1.5 – 3.0mm

Length tolerance: +15mm / -0mm

Weight tolerance: ±3 – 5%

III. PACKAGING

Bundle weight: 2.0 – 4.0 tons per bundle

IV. PRACTICAL APPLICATIONS

- Pre-engineered steel building frames and factory structures

- Load-bearing beams in high-rise buildings

- Bridge frameworks, piers, and support foundations

- Design of scaffolding structures and lifting gantries

- Industrial equipment and heavy machinery

- Manufacturing of trucks, ships, and containers

V. TOP I-BEAM STEEL BRANDS IN THE CURRENT MARKET

There are currently several well-known and reputable I-beam brands on the market, such as: Posco Yamato Vina, An Khanh Steel, Nippon Steel, Siam Yamato Steel, etc.

Technical Specifications of Posco Yamato Factory

Technical Specifications of An Khanh Factory

Technical Specifications of A Chau Factory

Angle Steel

Angle Steel U Beam

U Beam H Beam

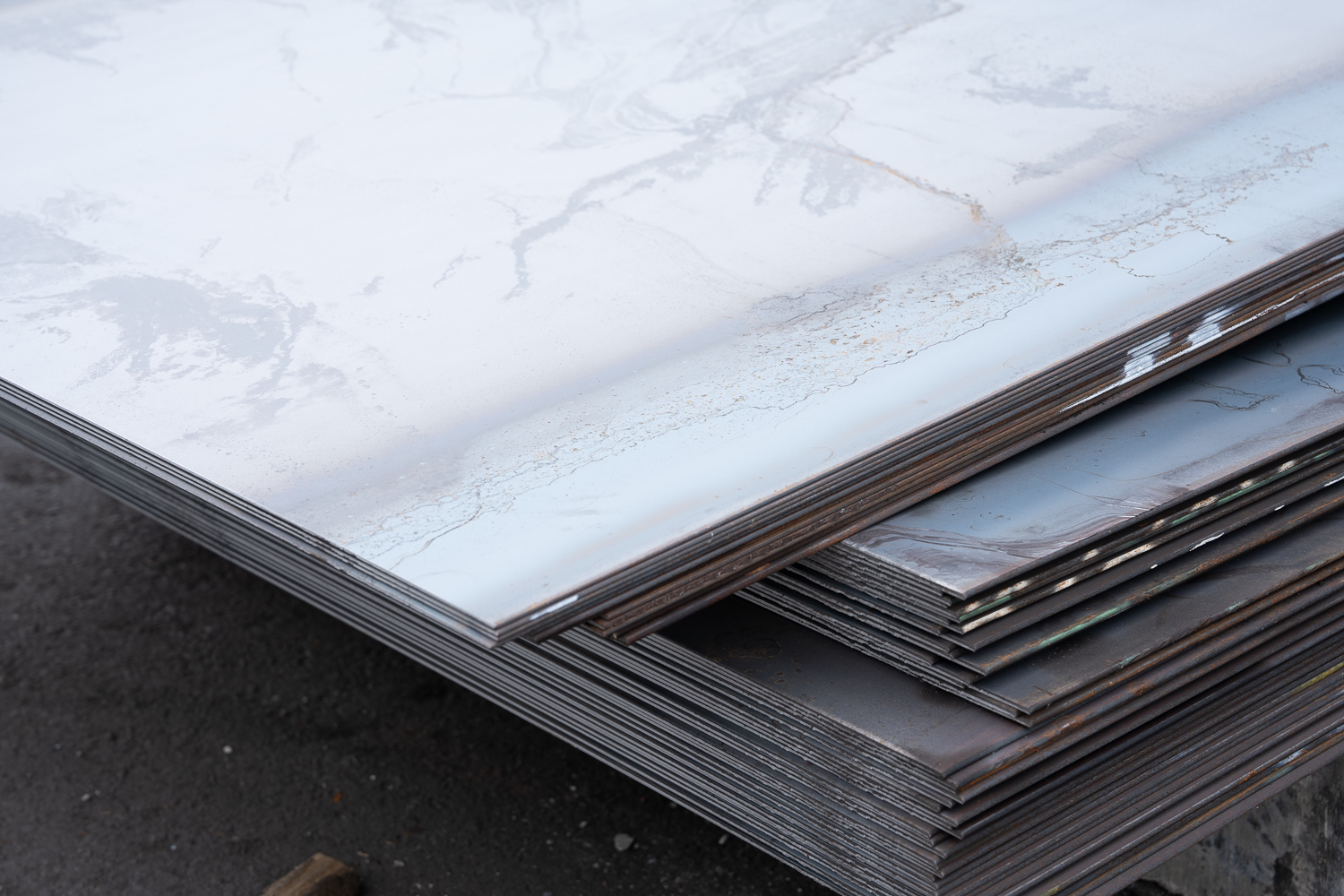

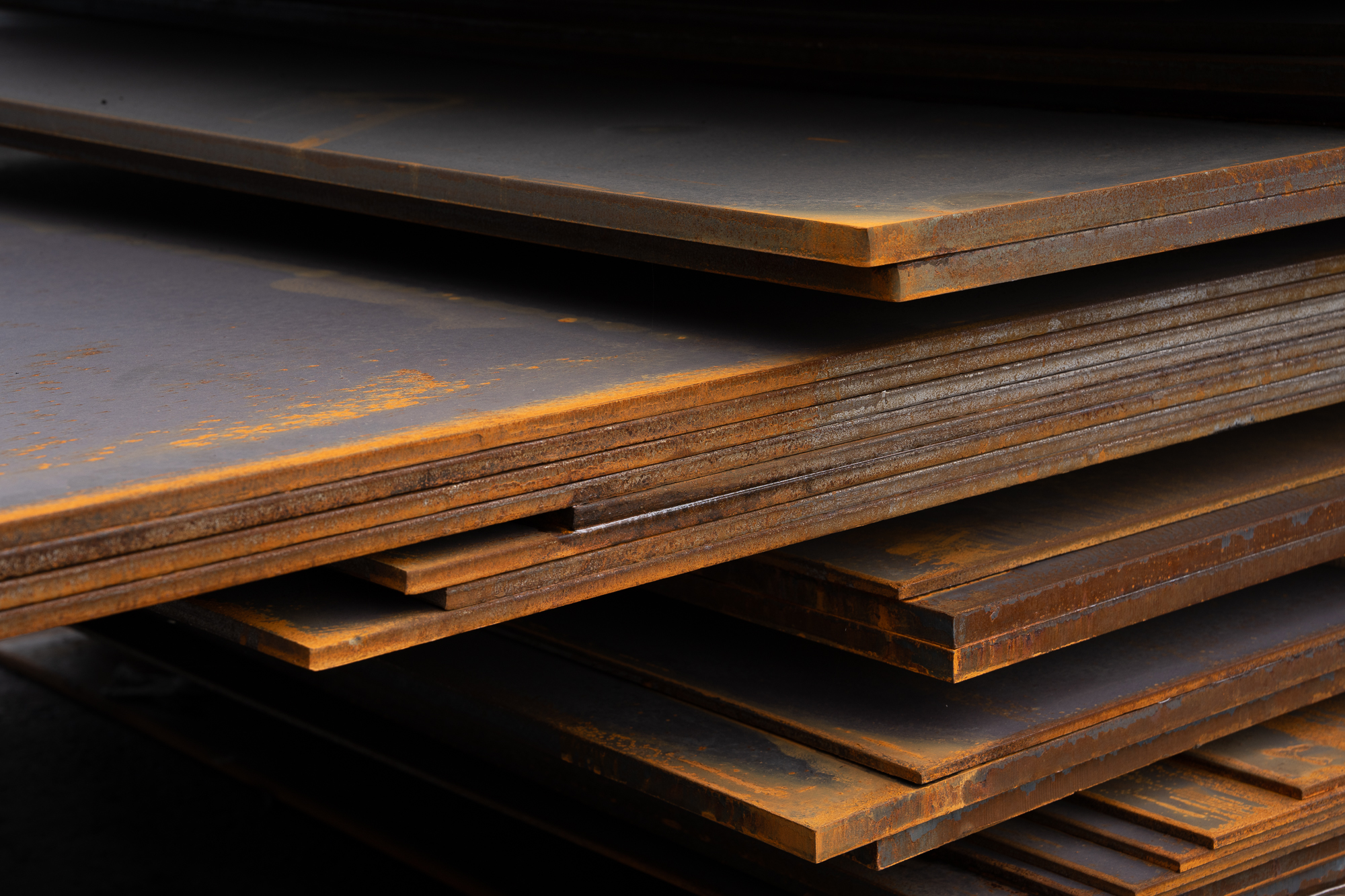

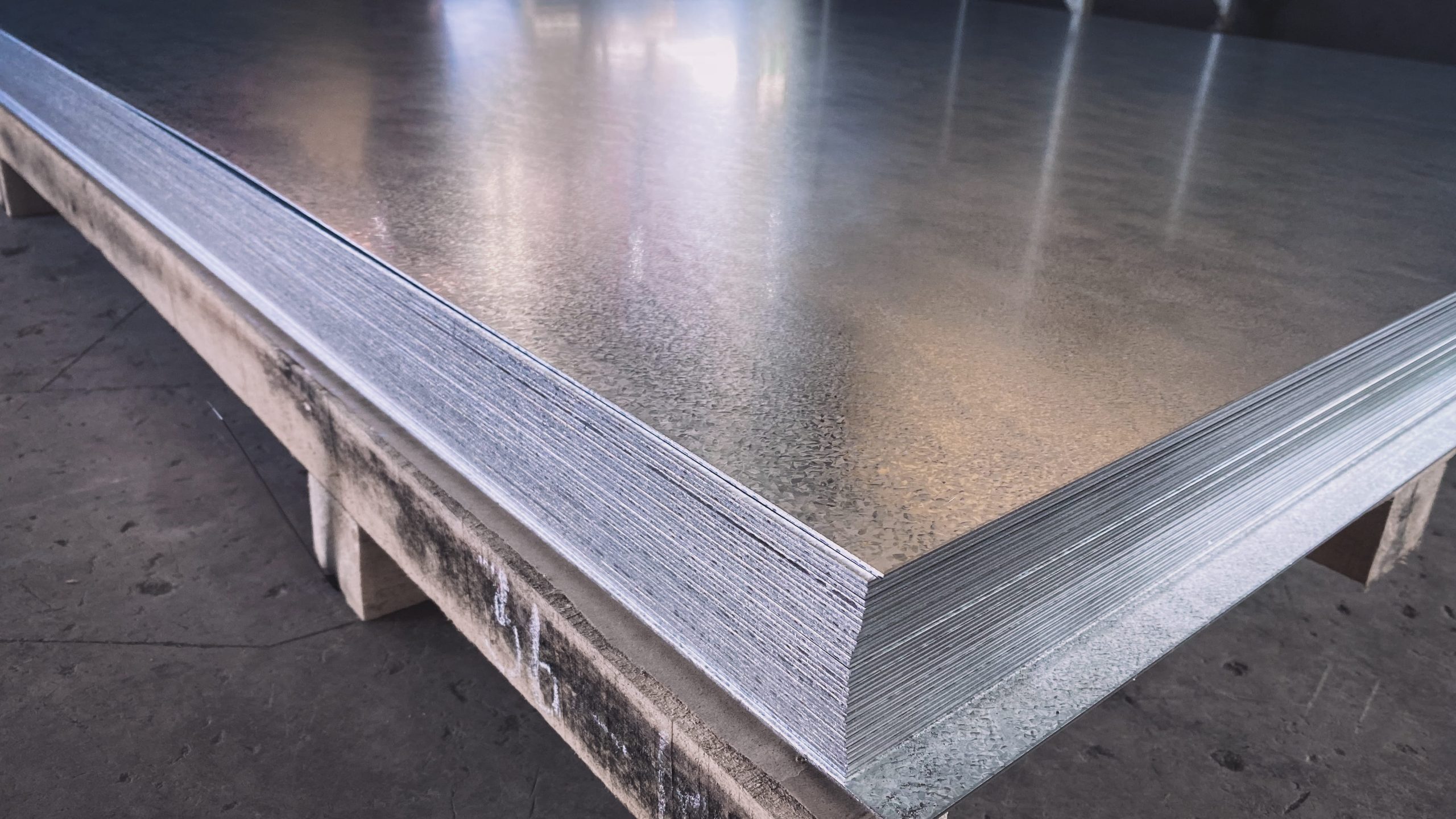

H Beam Steel Plate

Steel Plate Steel Sheet

Steel Sheet High Strength Steel Plate

High Strength Steel Plate Special Steel Plate

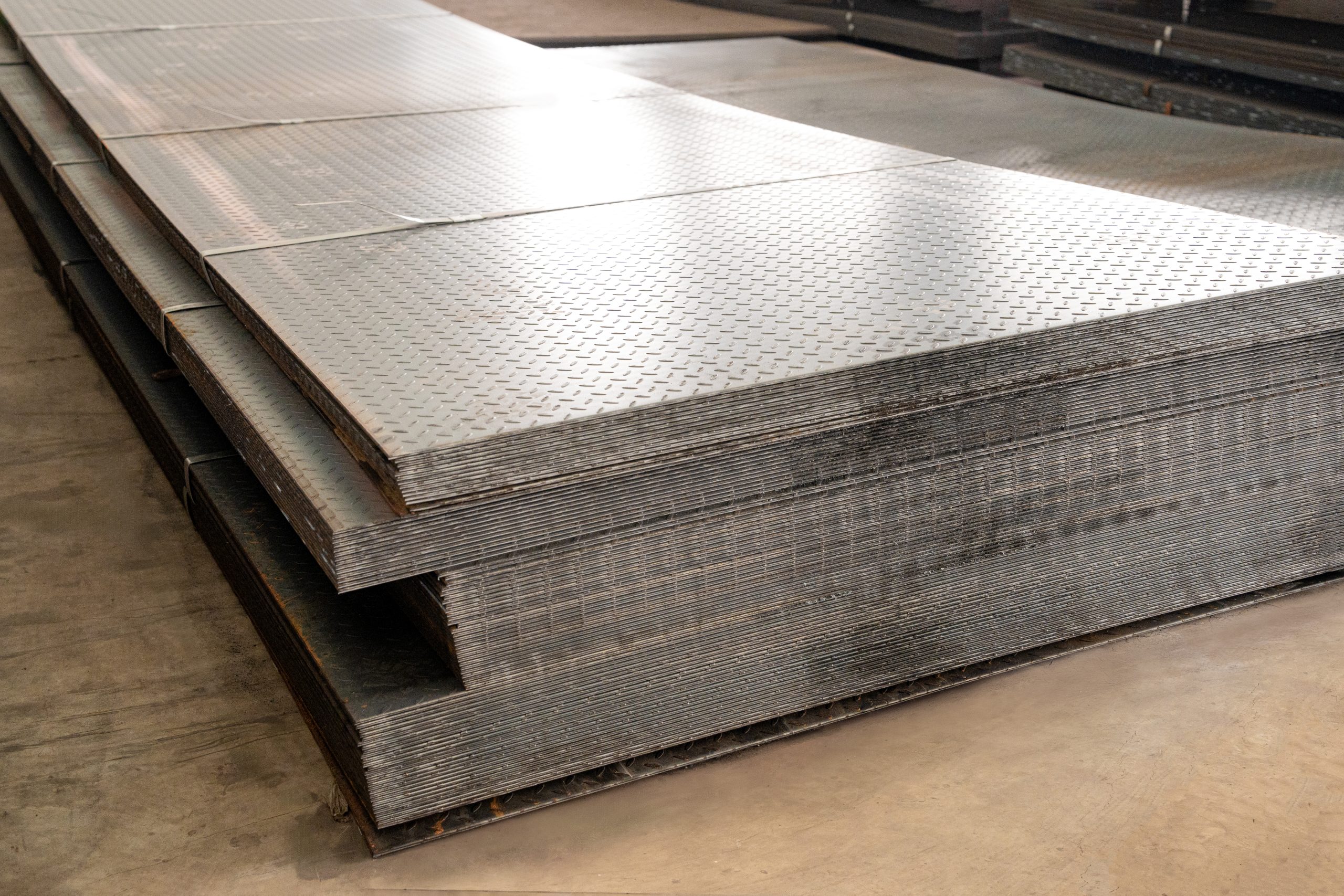

Special Steel Plate Checkered Steel Plate

Checkered Steel Plate Galvanized Steel Sheet

Galvanized Steel Sheet Hot Rolled Coil

Hot Rolled Coil Cold Rolled Coil

Cold Rolled Coil Galvanized Coil

Galvanized Coil Steel Strip

Steel Strip Square Bar

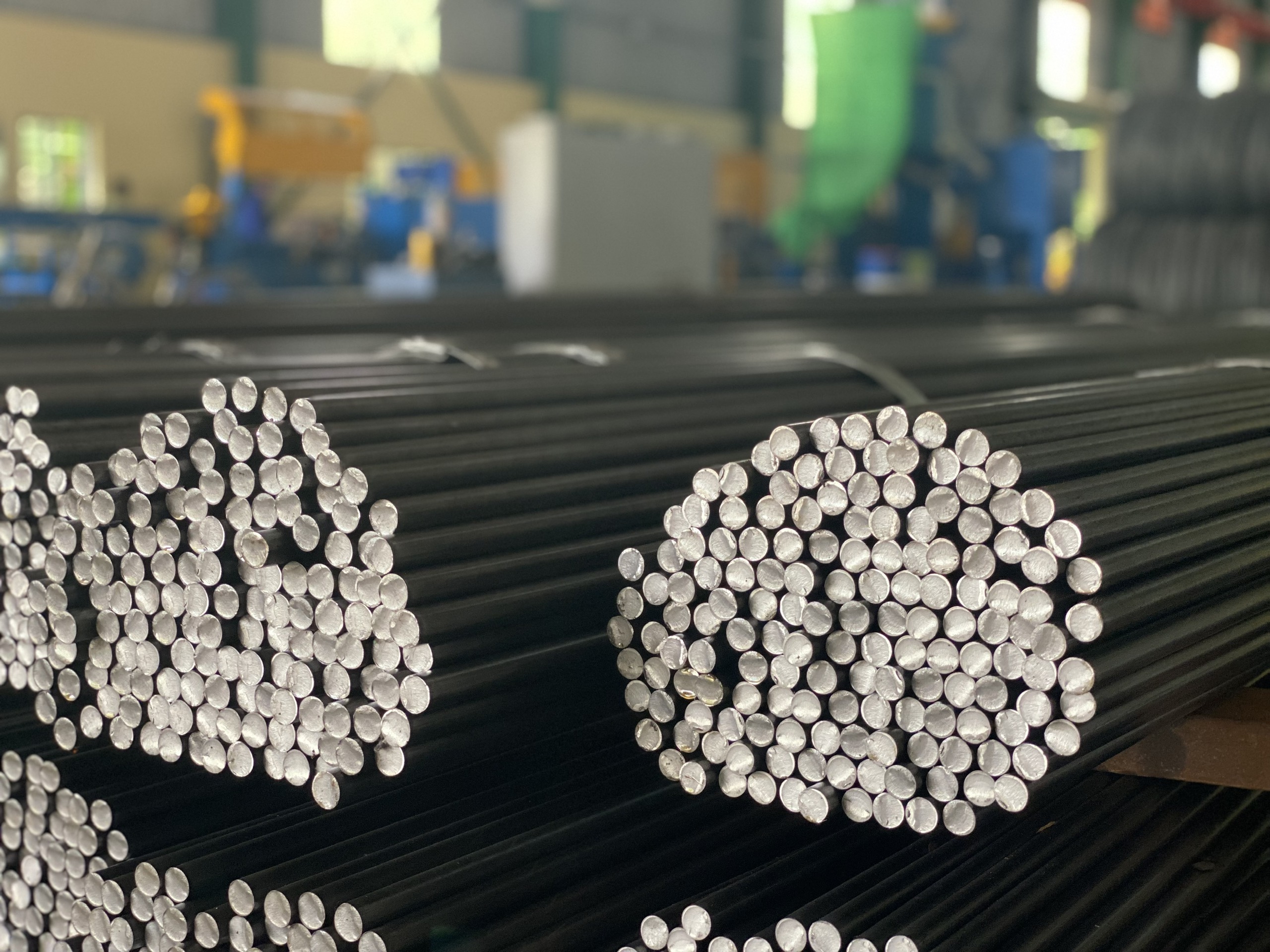

Square Bar Round Bar

Round Bar WELDED PIPE

WELDED PIPE Seamless Steel Pipe

Seamless Steel Pipe Steel tube

Steel tube Square Tube

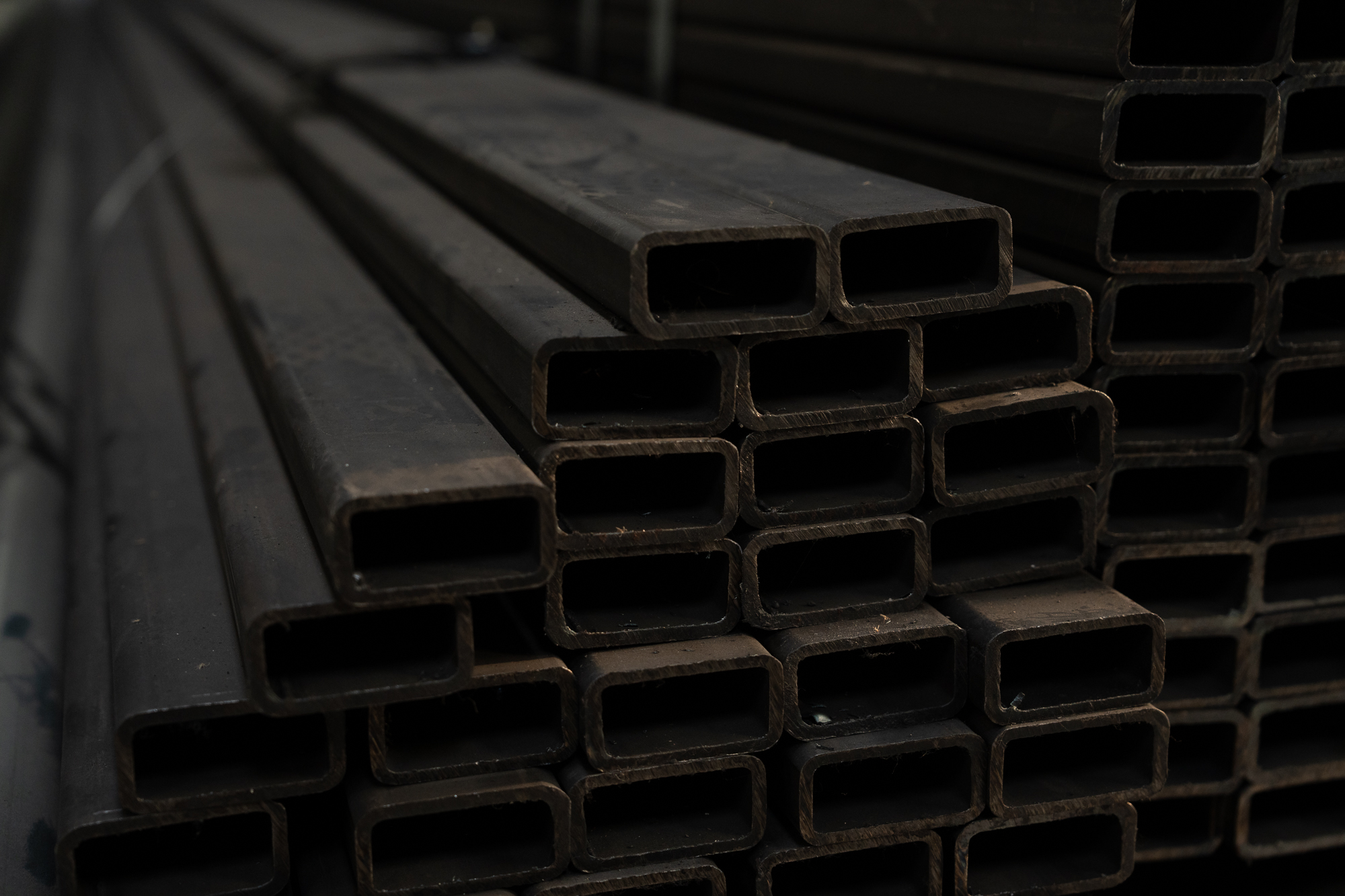

Square Tube Rectangular Tube

Rectangular Tube Wire Rod

Wire Rod Deformed Bar

Deformed Bar Steel Sheet Pile

Steel Sheet Pile Steel Purlin

Steel Purlin Steel Rail

Steel Rail Steel Fittings

Steel Fittings Stainless Steel

Stainless Steel Steel Fabrication

Steel Fabrication