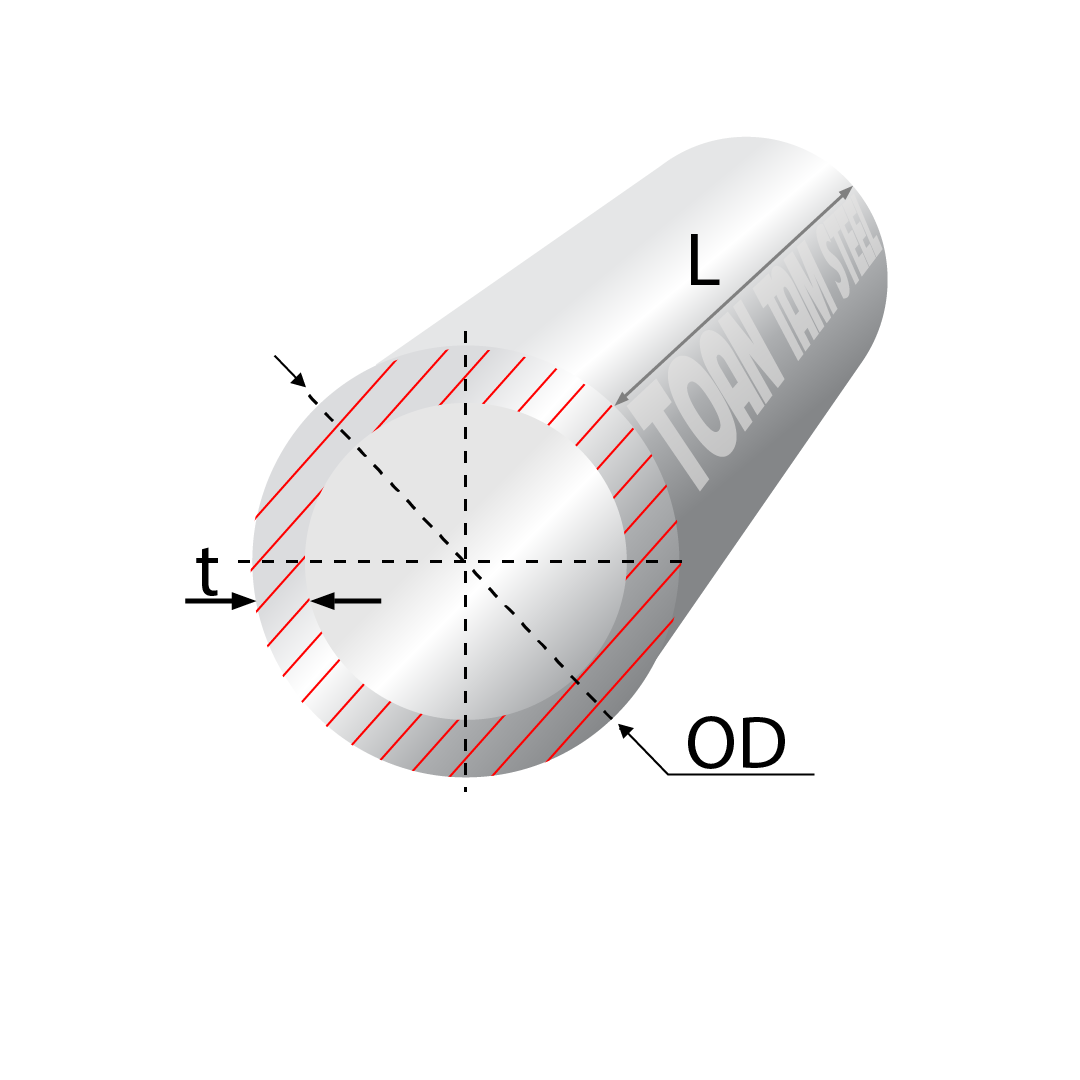

Seamless Steel Pipe

Seamless Steel Pipe

Outer diameter:

Φ10.3mm – Φ610mm or larger

Thickness:

2.41mm – 50mm (depending on diameter and application)

Length

6000mm – 12000mm

Grades:

A106 Gr. A/B/C, A53 Gr. B, API 5L

Mill

Tianjin, Baosteel, Hengyang, TPCO, JFE, Nippon Steel, SeAH Steel, HYSCO

Standards:

ASTM, API, JIS, GB

Key advantages:

- Superior strength and durability

- Better corrosion resistance

- Precise dimensions and tolerances

- Excellent performance in high-pressure conditions

- Wide range of applications

High production output

Large manufacturing capacity to efficiently fulfill bulk orders and key projects.

Competitive pricing

Offering budget-friendly yet competitive prices while maintaining product quality.

Trusted by clients

Chosen by hundreds of domestic and international clients for consistent quality and professional service.

Describe Product

Mục lục

Seamless steel pipe is a type of steel pipe without welds, produced by drawing or extruding a solid steel billet through a mold. Thanks to this special manufacturing process, seamless pipe offers higher strength and better resistance to pressure and temperature compared to welded steel pipe.

I. FEATURES

- Superior strength and durability: Seamless steel pipes are produced without welds, making them stronger and capable of withstanding high pressure, temperature, and mechanical stress. They are suitable for high-performance applications such as oil & gas, power plants, and chemical industries.

- Uniform shape and structure: Seamless pipes have a consistent round cross-section. With no weak points or weld seams, the risk of failure under heavy loads is significantly reduced.

- Better corrosion resistance: A smooth surface and fewer imperfections help prevent the onset of corrosion. They are often preferred in harsh environments where long service life is essential.

- Precise dimensions and tolerances: The seamless manufacturing process ensures high dimensional accuracy,

making installation and connections easier and more efficient. - Excellent performance in high-pressure conditions: Commonly used in hydraulic systems, boilers, and other high-pressure applications. They are less likely to crack or fail under extreme conditions.

- Wide range of applications: Widely used in industries such as oil & gas, petrochemicals, automotive, aerospace, and construction.

| Tính chất vật lý(Mechanical Properties) | Tính chất hoá học(Chemical Composition) | |||||||

|---|---|---|---|---|---|---|---|---|

| Mác thép(Grade) | Độ bền chảy(Yeild Strength) (Mpa ~ N/mm2) Min |

Độ bền kéo(Tensile Strength) (Mpa ~ N/mm2) Min |

Độ giãn dài(Elongation) % |

C% | Si% | Mn% | P% | S% |

| SS400 | ≥ 245* | 400 – 510 | ≥ 21 | ≤ 0.29 | ≤ 0.40 | ≤ 1.6 | ≤ 0.050 | ≤ 0.050 |

| A36 | ≥ 250 | 400 – 550 | ≥ 20 | ≤ 0.26 | ≤ 0.40 | ≤ 0.040 | ≤ 0.050 | |

| Q235B | ≥ 235* | 375 – 500 | ≥ 26* | ≤ 0.20 | ≤ 0.30 | 0.30 – 0.70 | ≤ 0.045 | ≤ 0.045 |

| A572 Gr50 | ≥ 345* | 450 – 620 | ≥ 18 | ≤ 0.23 | 0.15 – 0.40 | 1.35 – 1.65 | ≤ 0.040 | ≤ 0.050 |

| Q355B | ≥ 355* | 470 – 630 | ≥ 22 | ≤ 0.24 | ≤ 0.55 | ≤ 1.6 | ≤ 0.035 | ≤ 0.035 |

II. TOLERANCE

Diameter tolerance: ±0.5 – ±1.0%

Weight tolerance: ± 12.5%

Length tolerance: ± 50mm

III. PACKAGING

Bundle weight: 1.5 – 3 metric tons per bundle

IV. PRACTICAL APPLICATIONS

- Oil & gas industry: oil and gas pipelines, drilling pipes

- Thermal power – boilers: heat-resistant pipes, high-pressure pipes

- Chemical industry: chemical transport, acid-resistant, corrosion-resistant applications

- Machinery manufacturing: shaft tubes, bushings, hydraulic pipes

- Construction: pipe piles, industrial structures, wind power plant structures

Angle Steel

Angle Steel U Beam

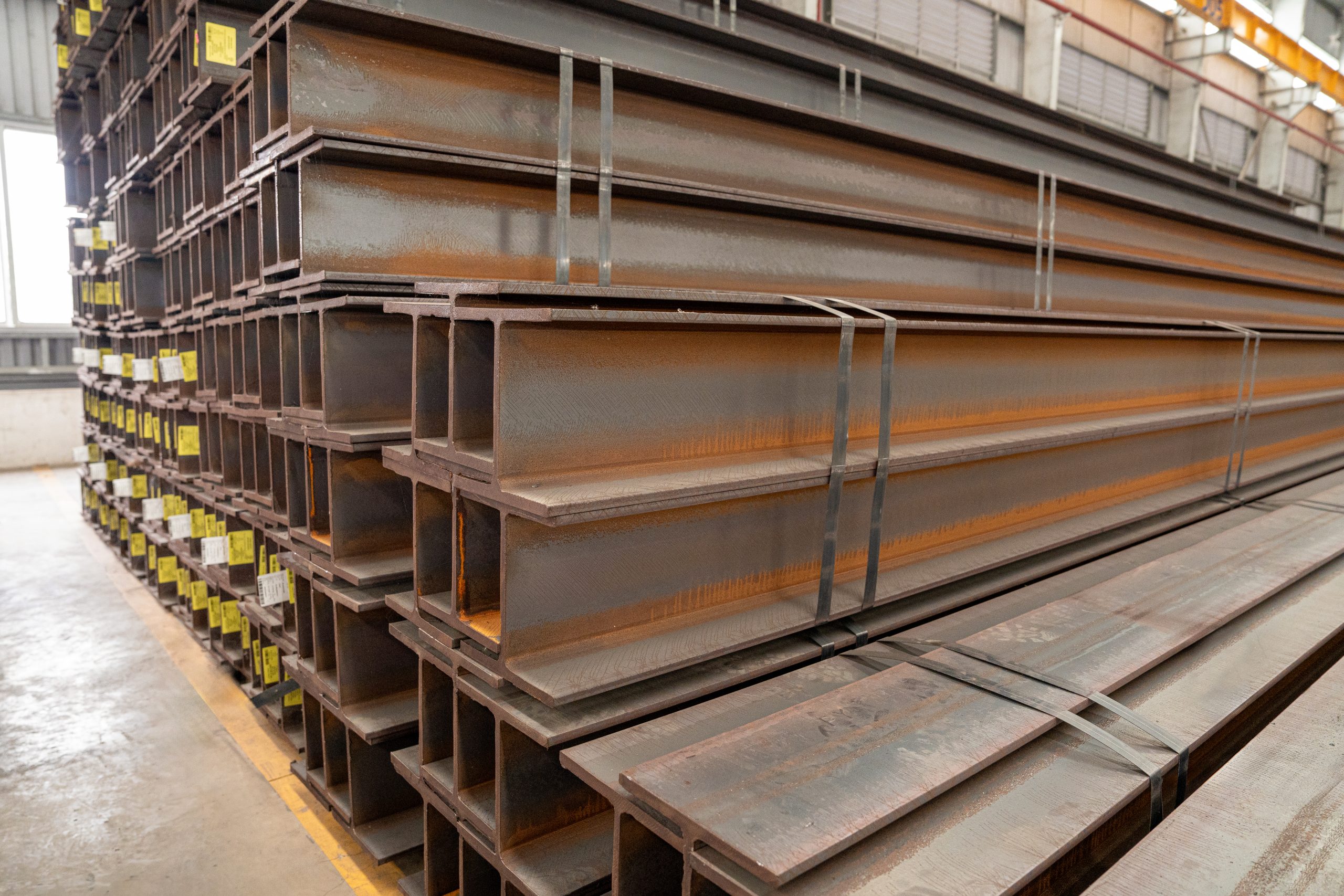

U Beam H Beam

H Beam I-BEAM

I-BEAM Steel Plate

Steel Plate Steel Sheet

Steel Sheet High Strength Steel Plate

High Strength Steel Plate Special Steel Plate

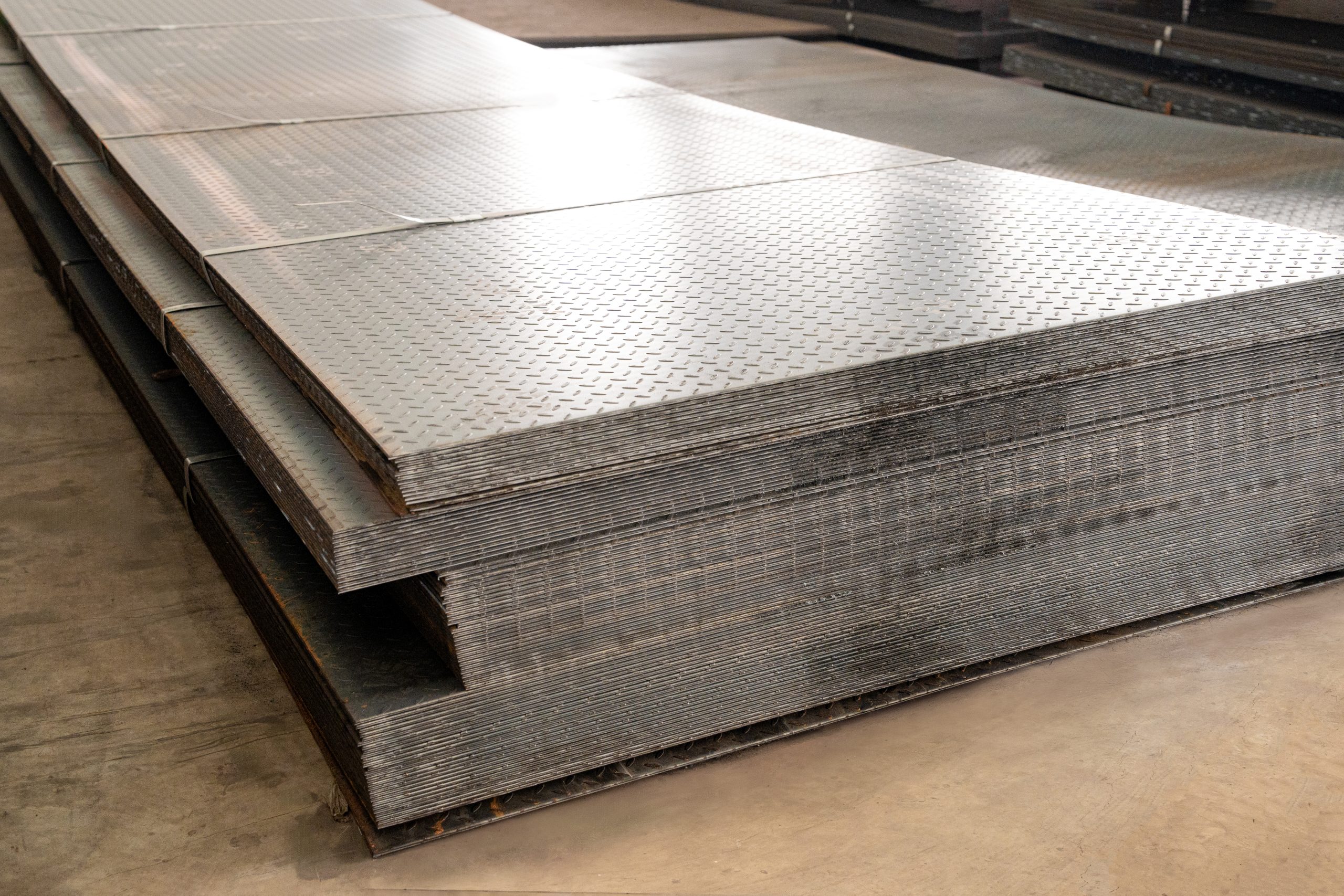

Special Steel Plate Checkered Steel Plate

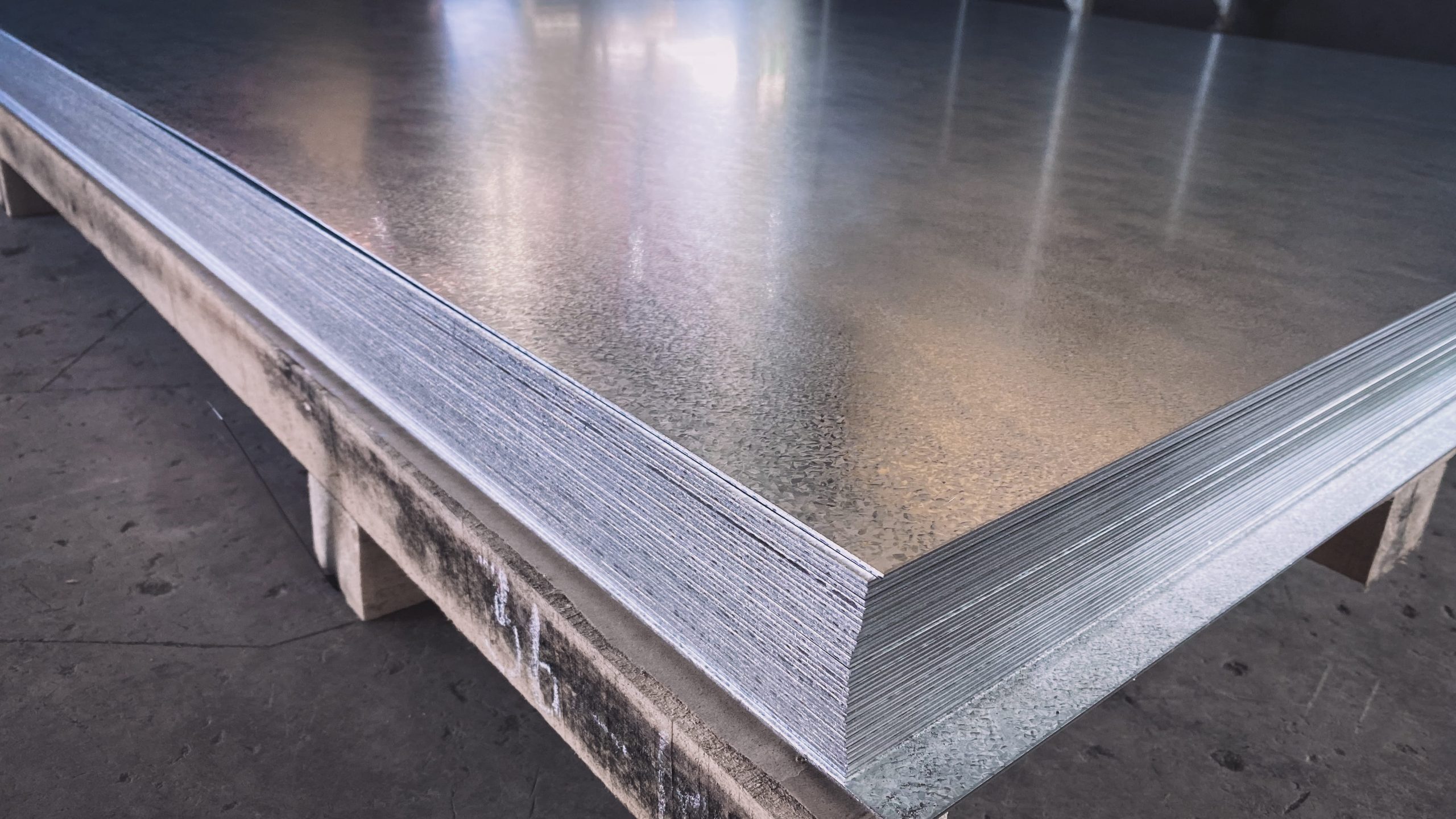

Checkered Steel Plate Galvanized Steel Sheet

Galvanized Steel Sheet Hot Rolled Coil

Hot Rolled Coil Cold Rolled Coil

Cold Rolled Coil Galvanized Coil

Galvanized Coil Steel Strip

Steel Strip Square Bar

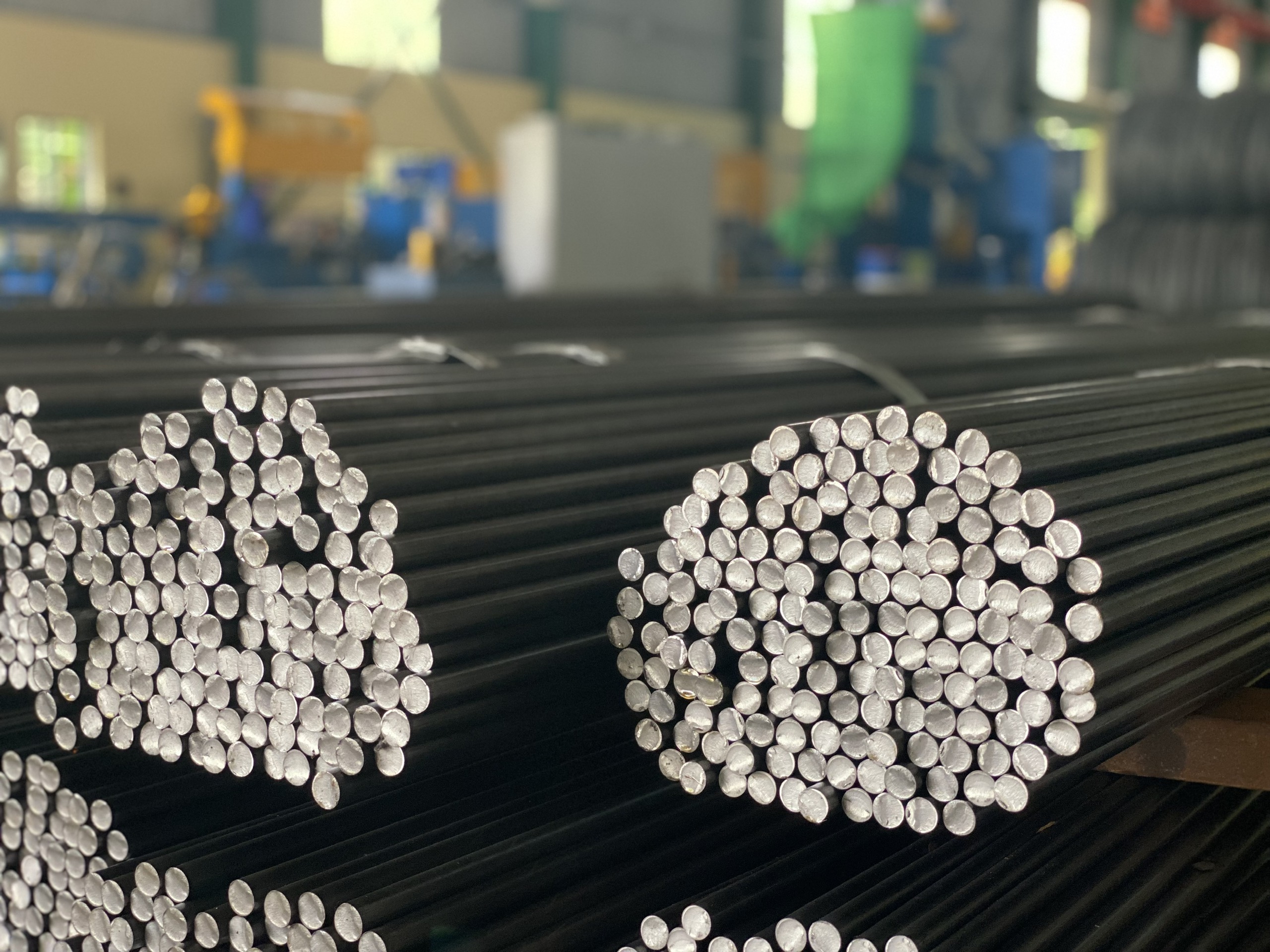

Square Bar Round Bar

Round Bar WELDED PIPE

WELDED PIPE Seamless Steel Pipe

Seamless Steel Pipe Steel tube

Steel tube Square Tube

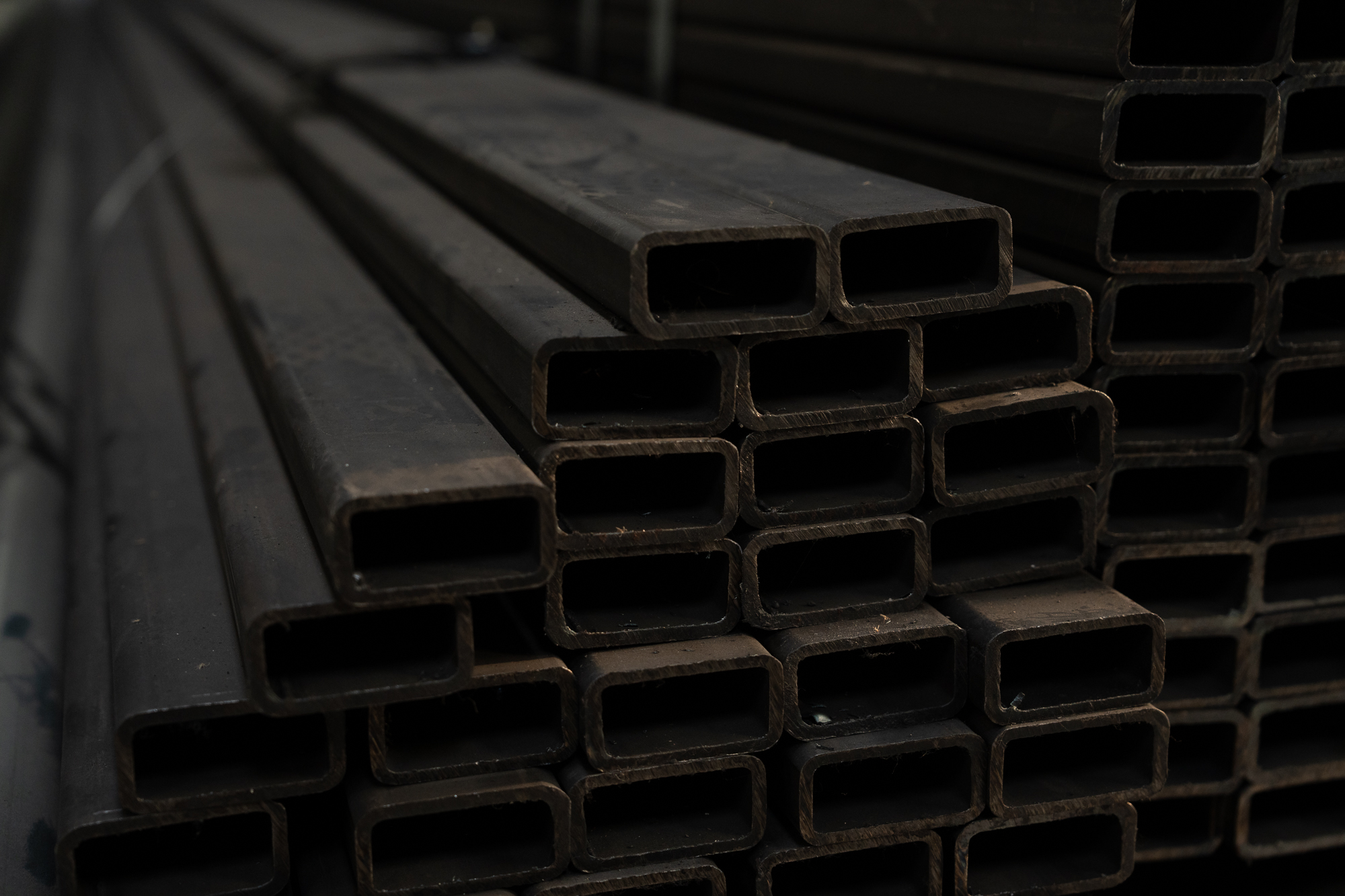

Square Tube Rectangular Tube

Rectangular Tube Wire Rod

Wire Rod Deformed Bar

Deformed Bar Steel Sheet Pile

Steel Sheet Pile Steel Purlin

Steel Purlin Steel Rail

Steel Rail Steel Fittings

Steel Fittings Stainless Steel

Stainless Steel Steel Fabrication

Steel Fabrication