WELDED PIPE

WELDED PIPE

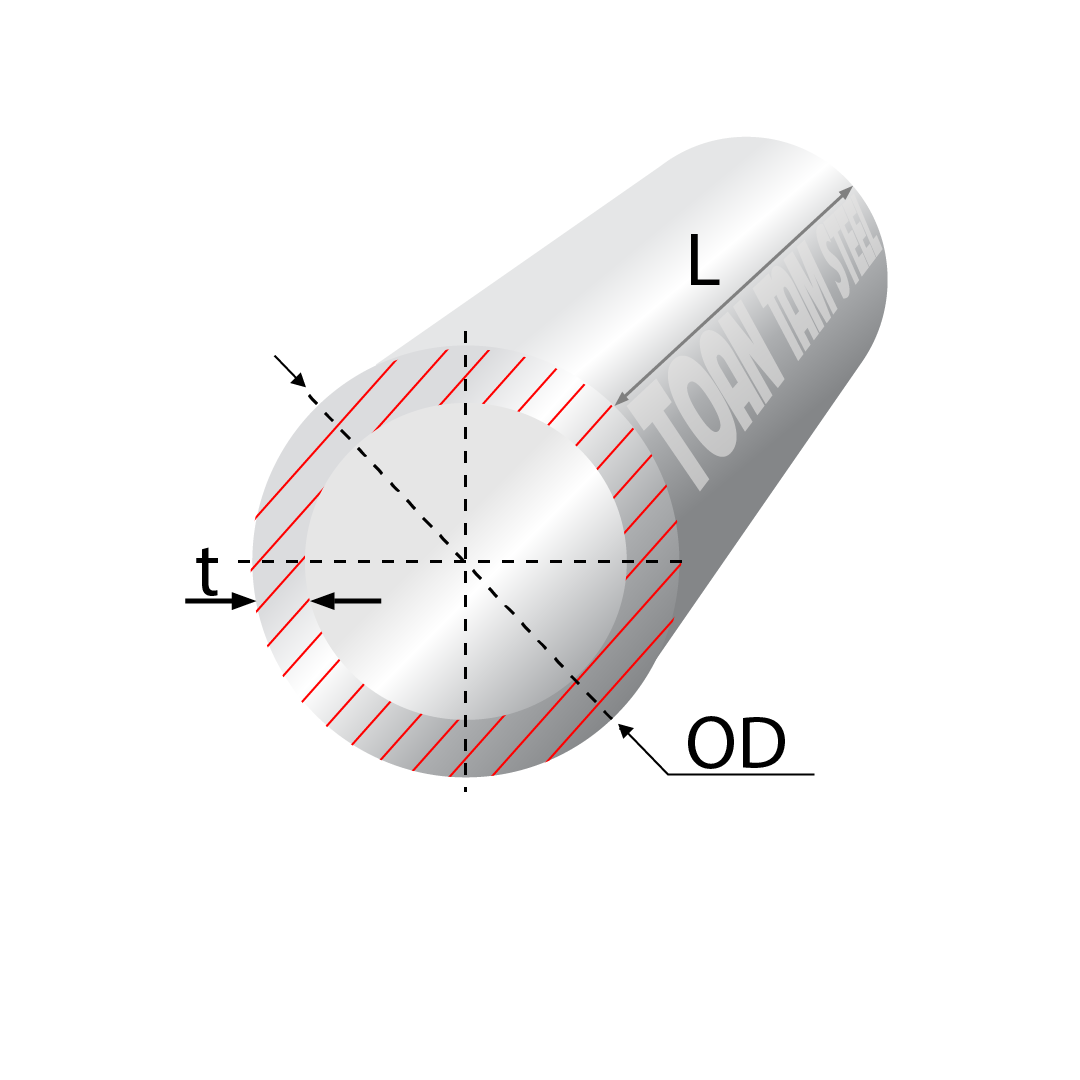

Diameter:

From 12.7mm to 508mm (or as requested)

Wall thickness:

From 0.6mm to 12mm

Standard length:

6,000mm / 12,000mm or cut-to-size

Grades:

A500 grade A/B, A53 grade A/B, , STK400, API 5L grade A/B, etc

Mills:

Hoa Phat, Phu Xuan Viet, 190, TVP, Visa, Sai Gon Steel, Nam Hung, Duc Viet, SeAH, Shandong, Baotou, etc

Standards:

ASTM A500, ASTM A53, JIS G3444, API 5L...

Key Advantages:

- Cost-effective

- Wide range of available diameters and wall thicknesses

- Suitable for a variety of purposes

- Good corrosion and rust resistance

- High aesthetic appeal and lightweight

- High efficiency in mass production

- Easy fabrication and assembly

High production output

Large manufacturing capacity to efficiently fulfill bulk orders and key projects.

Competitive pricing

Offering budget-friendly yet competitive prices while maintaining product quality.

Trusted by clients

Chosen by hundreds of domestic and international clients for consistent quality and professional service.

Describe Product

Mục lục

Welded pipes are manufactured from steel coils using advanced welding technologies such as ERW, LSAW, and SSAW. They offer an economical and flexible solution for structural construction, machinery frames, and fluid transport systems. The pipes feature a wide range of diameters, high uniformity, and are easy to cut, weld, and surface-treat, such as galvanizing for enhanced durability.

I. FEATURES

- Cost-effectiveness

The production process of welded pipes (typically from steel coils or strips) is simpler and more efficient compared to seamless pipe manufacturing (which require piercing a solid steel billet). This helps save raw materials and energy, resulting in significantly lower costs for welded pipes of the same size. - Wide range of diameters and wall thicknesses

Welded pipes can be manufactured with very large outer diameters, from a few centimeters to several meters (e.g., for large-scale oil or water pipelines). This is difficult or impossible to achieve with seamless pipes. Moreover, the wall thickness of welded pipes is highly uniform. - Suitable for various applications

Ideal for civil and industrial construction; conveying low to medium-pressure fluids; and for machinery frames, furniture, and interior decoration. - Good corrosion and rust resistance

Especially when galvanized or powder-coated, welded steel pipes can withstand harsh environments such as humidity, chemicals, or outdoor conditions. - High aesthetic appeal and lightweight

With a hollow design, welded pipes provide structural rigidity while reducing weight, which helps to decrease the load on structures. Additionally, the surface of welded pipes is usually smooth, making it easy to apply finishes like painting or galvanizing. - High efficiency in mass production

Continuous welding processes (ERW, LSAW, SSAW) allow for stable, large-scale production, suitable for major projects. - Ease of fabrication and installation

Welded pipes are easy to cut, bend, drill, and weld with other fittings, offering flexibility in design and construction.

| Tính chất vật lý(Mechanical Properties) | Tính chất hoá học(Chemical Composition) | |||||||

|---|---|---|---|---|---|---|---|---|

| Mác thép(Grade) | Độ bền kéo (Tensile Strength) (MPa) |

Độ bền kéo (Tensile Strength) (MPa) |

Độ giãn dài(Elongation) % |

C% | Si% | Mn% | P% | S% |

| ASTM A500 grade A | ≥ 230 | ≥ 310 | ≥ 25 | ≤ 0.26 | – | ≤ 1.35 | ≤ 0.035 | ≤ 0.035 |

| ASTM A500 grade B | ≥ 290 | ≥ 400 | ≥ 23 | ≤ 0.26 | – | ≤ 1.35 | ≤ 0.035 | ≤ 0.035 |

| ASTM A53 grade A | ≥ 205 | ≥ 330 | ≥ 22 | ≤ 0.25 | – | ≤ 0.95 | ≤ 0.050 | ≤ 0.045 |

| ASTM A53 grade B | ≥ 240 | ≥ 415 | ≥ 18 | ≤ 0.30 | – | ≤ 1.20 | ≤ 0.050 | ≤ 0.045 |

| STK400 | ≥ 235 | ≥ 400 | ≥ 23 | ≤ 0.25 | – | – | ≤ 0.040 | ≤ 0.040 |

II. TOLERANCE

Wall thickness tolerance: ±5 – 12.5% (varies by standards)

Diameter tolerance: ±0.5 – 1.0% (varies by sizes and standards)

Weight tolerance: ±10%

III. PACKAGING

Bundle weight: 300 – 2000kg/bundle

IV. PRACTICAL APPLICATIONS

- Construction: Scaffolding, steel structures, pre-engineered building frames, fences, etc

- Mechanical & fire protection systems: Water pipelines, gas pipelines, fire protection systems, etc

- Manufacturing industry: Oil and chemical pipelines, machinery frames, etc

- Agriculture: Greenhouse frames, support columns, irrigation systems, etc

- Household & furniture industry: Steel tables and chairs, door frames, metal shelves, etc

V. TOP WELDED PIPE BRANDS IN THE CURRENT MARKET

Currently, there are several well-known and reputable welded pipe brands on the market, including: Hoa Phat, Phu Xuan Viet, Sai Gon Steel, Duc Viet, SeAH, ...

Technical Specifications of Phu Xuan Viet Factory

Technical Specifications of Hoa Phat Factory

Technical Specifications of Sai Gon Factory

Angle Steel

Angle Steel U Beam

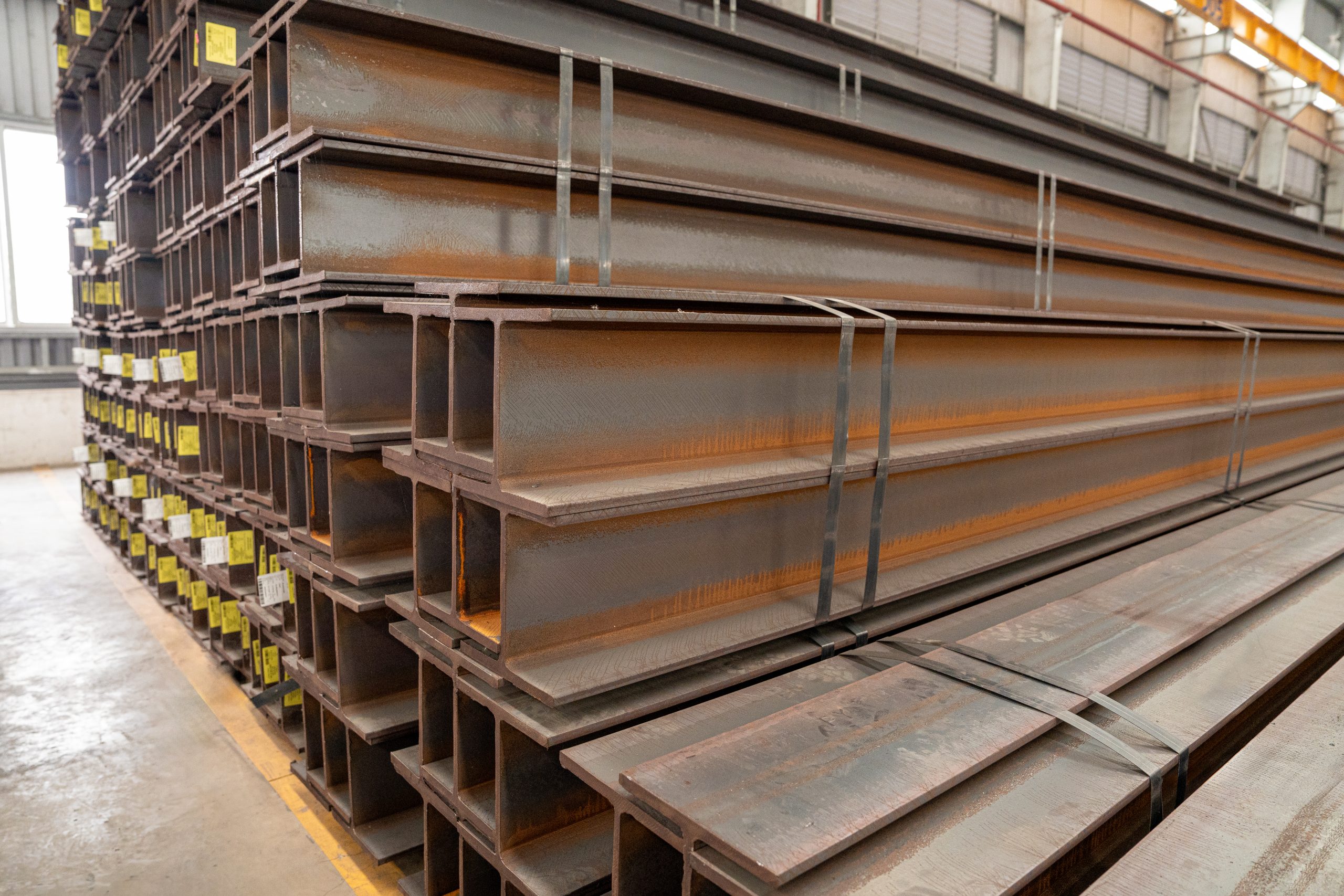

U Beam H Beam

H Beam I-BEAM

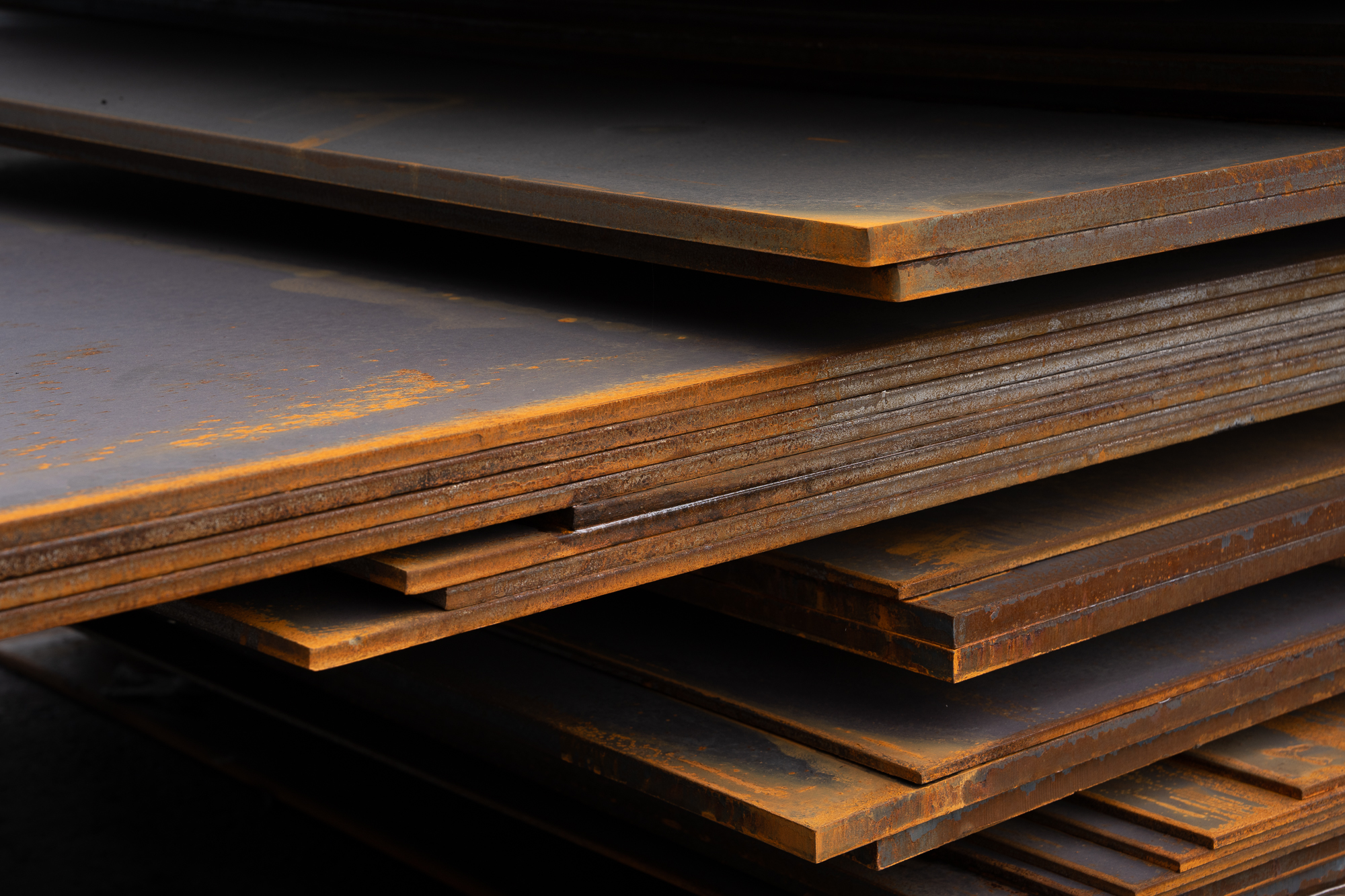

I-BEAM Steel Plate

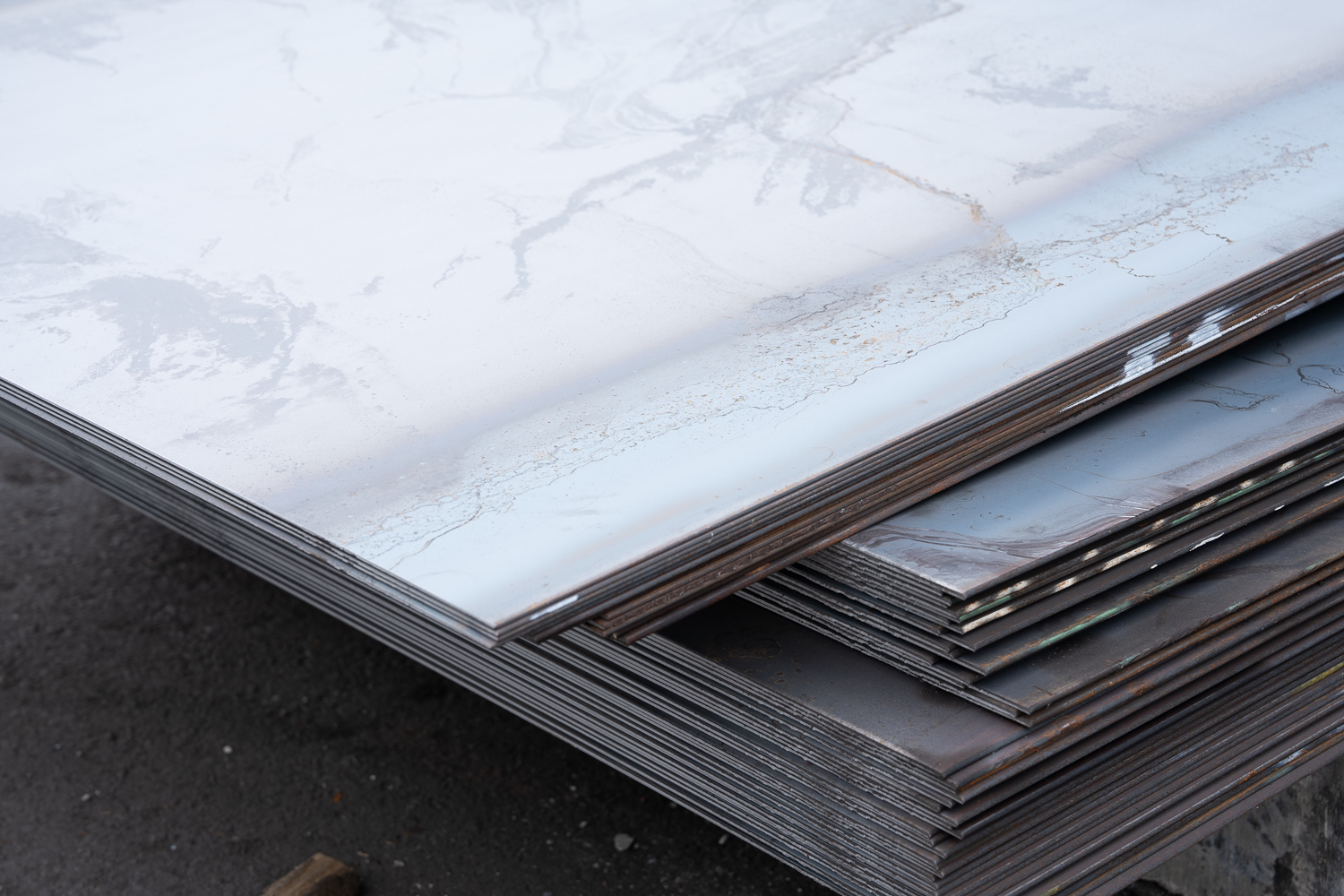

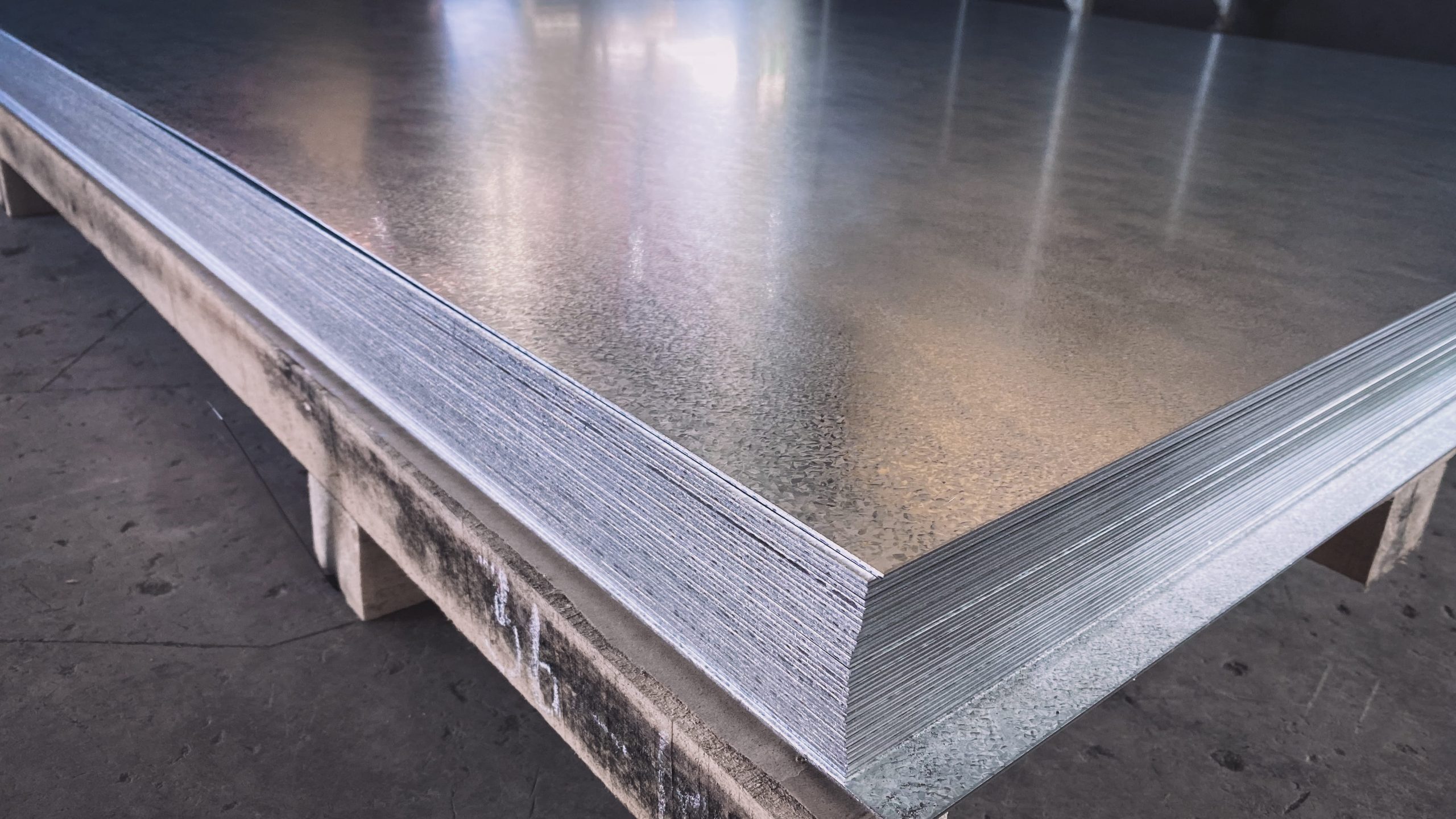

Steel Plate Steel Sheet

Steel Sheet High Strength Steel Plate

High Strength Steel Plate Special Steel Plate

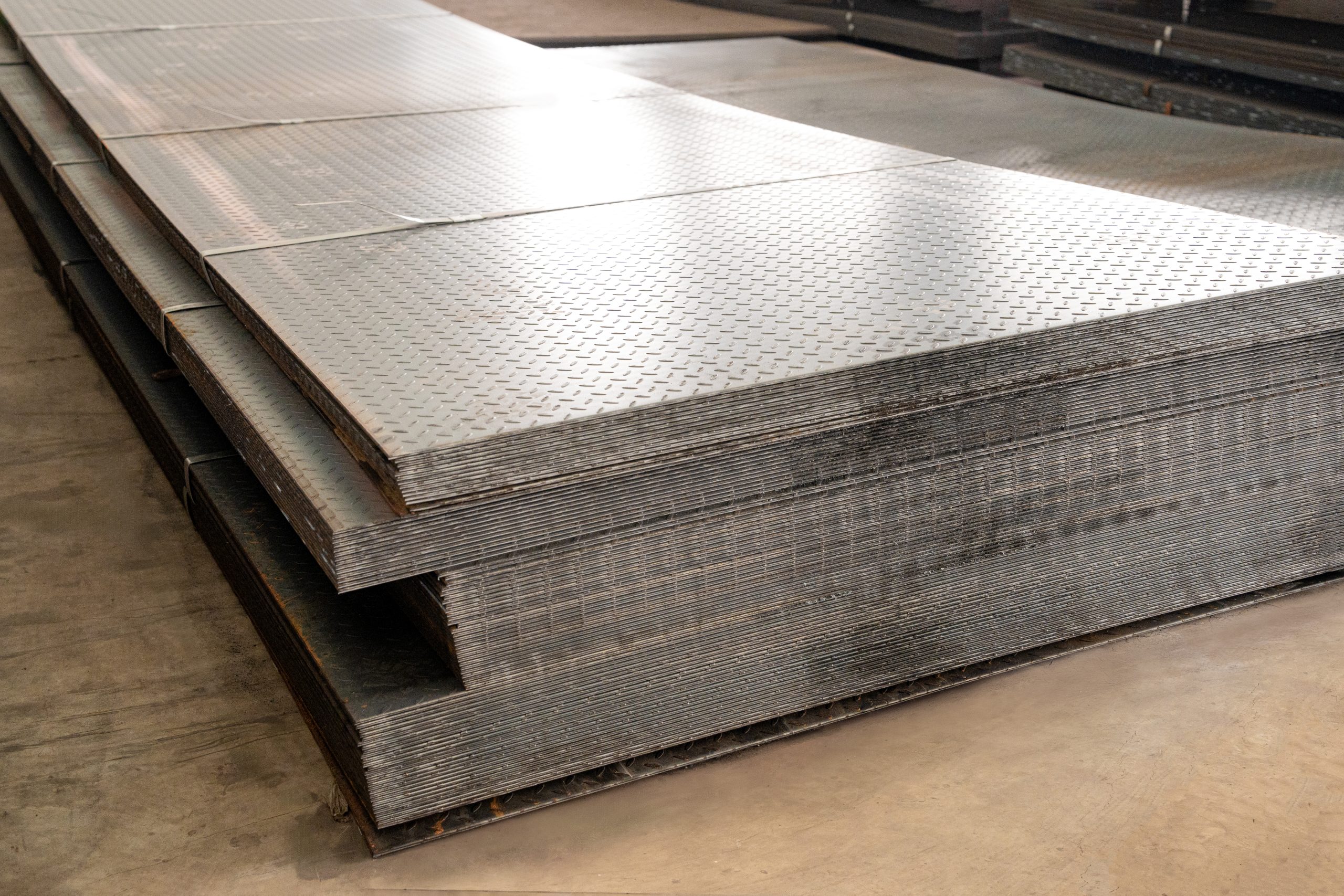

Special Steel Plate Checkered Steel Plate

Checkered Steel Plate Galvanized Steel Sheet

Galvanized Steel Sheet Hot Rolled Coil

Hot Rolled Coil Cold Rolled Coil

Cold Rolled Coil Galvanized Coil

Galvanized Coil Steel Strip

Steel Strip Square Bar

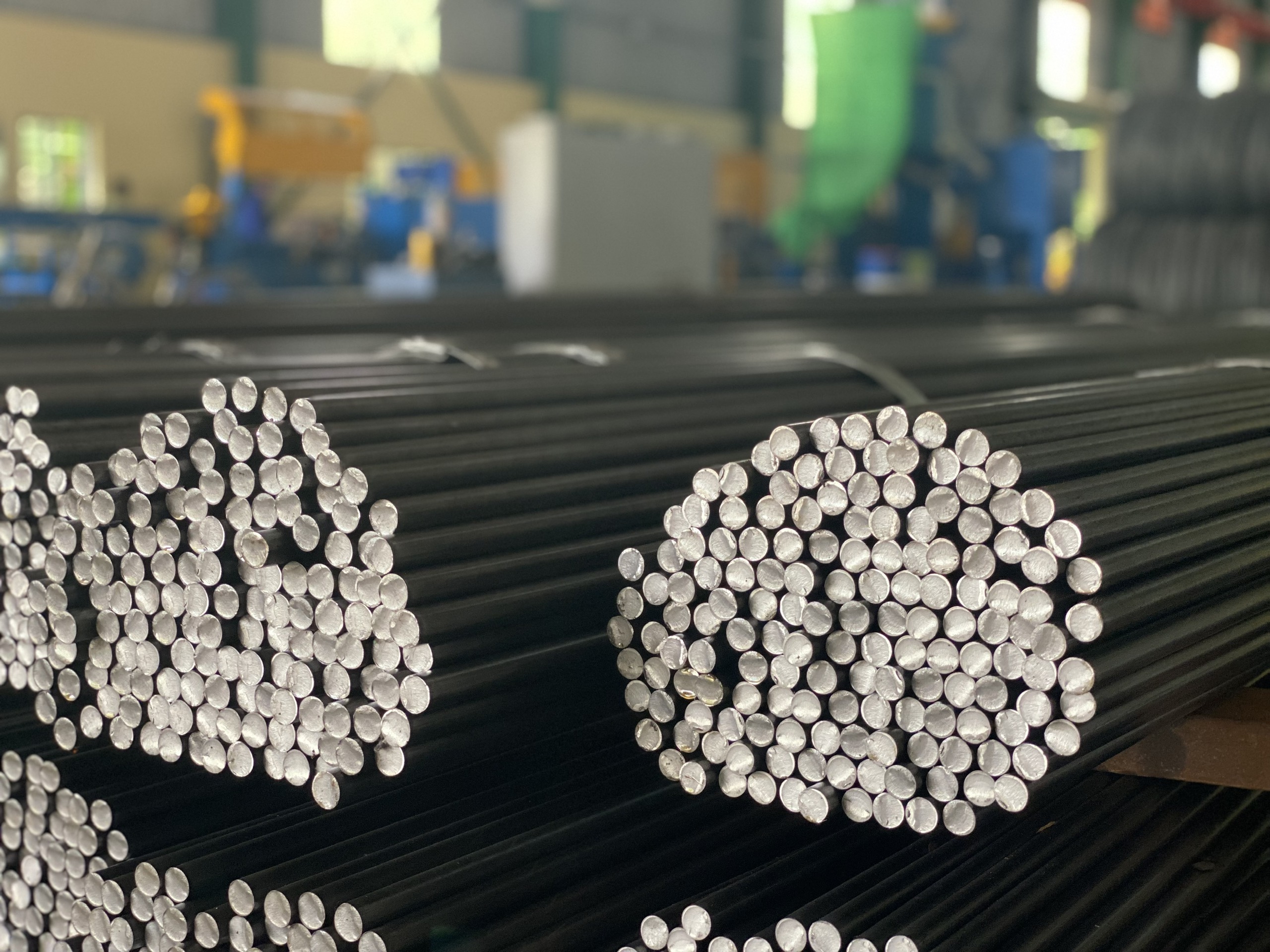

Square Bar Round Bar

Round Bar WELDED PIPE

WELDED PIPE Seamless Steel Pipe

Seamless Steel Pipe Steel tube

Steel tube Square Tube

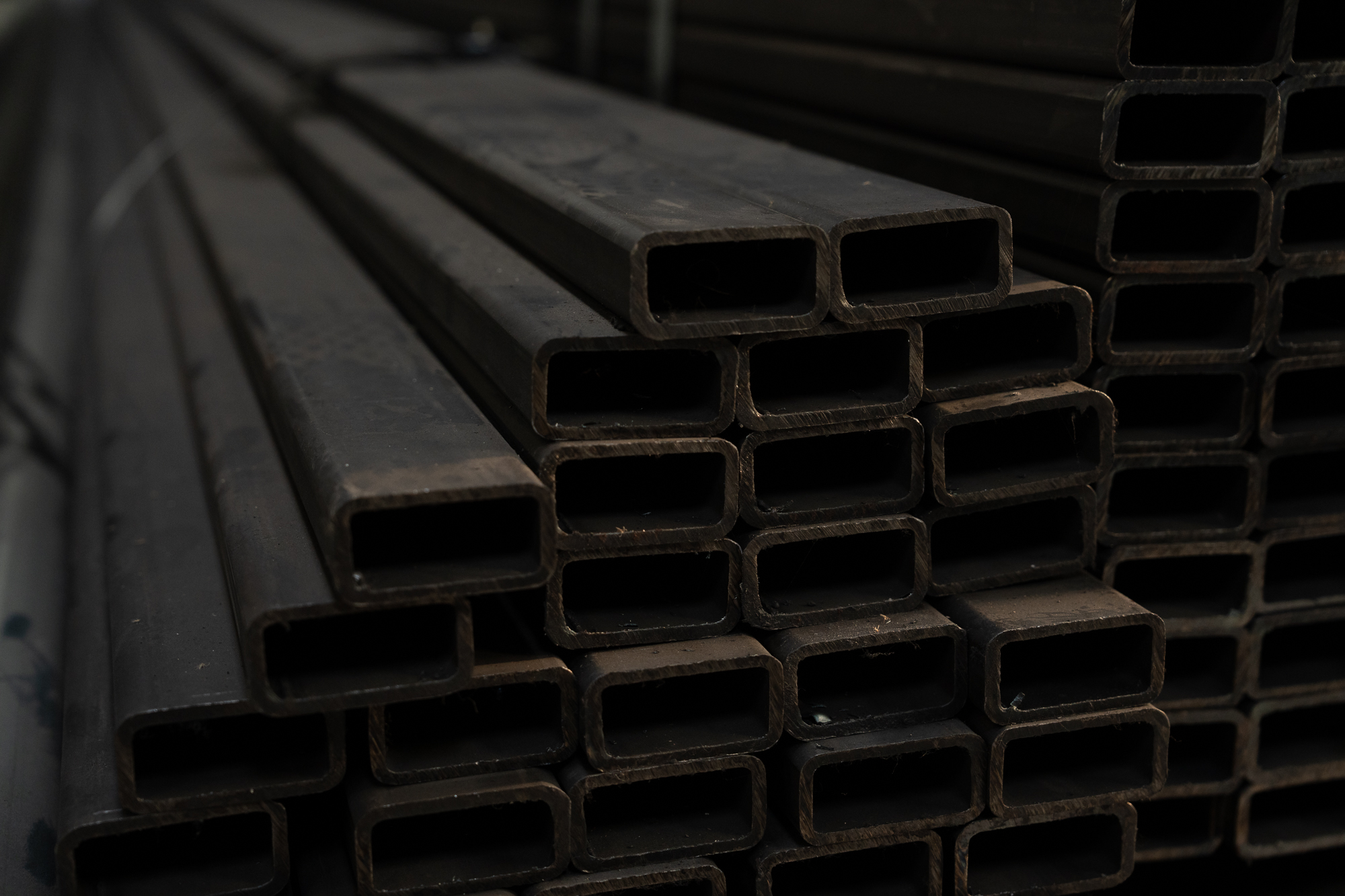

Square Tube Rectangular Tube

Rectangular Tube Wire Rod

Wire Rod Deformed Bar

Deformed Bar Steel Sheet Pile

Steel Sheet Pile Steel Purlin

Steel Purlin Steel Rail

Steel Rail Steel Fittings

Steel Fittings Stainless Steel

Stainless Steel Steel Fabrication

Steel Fabrication