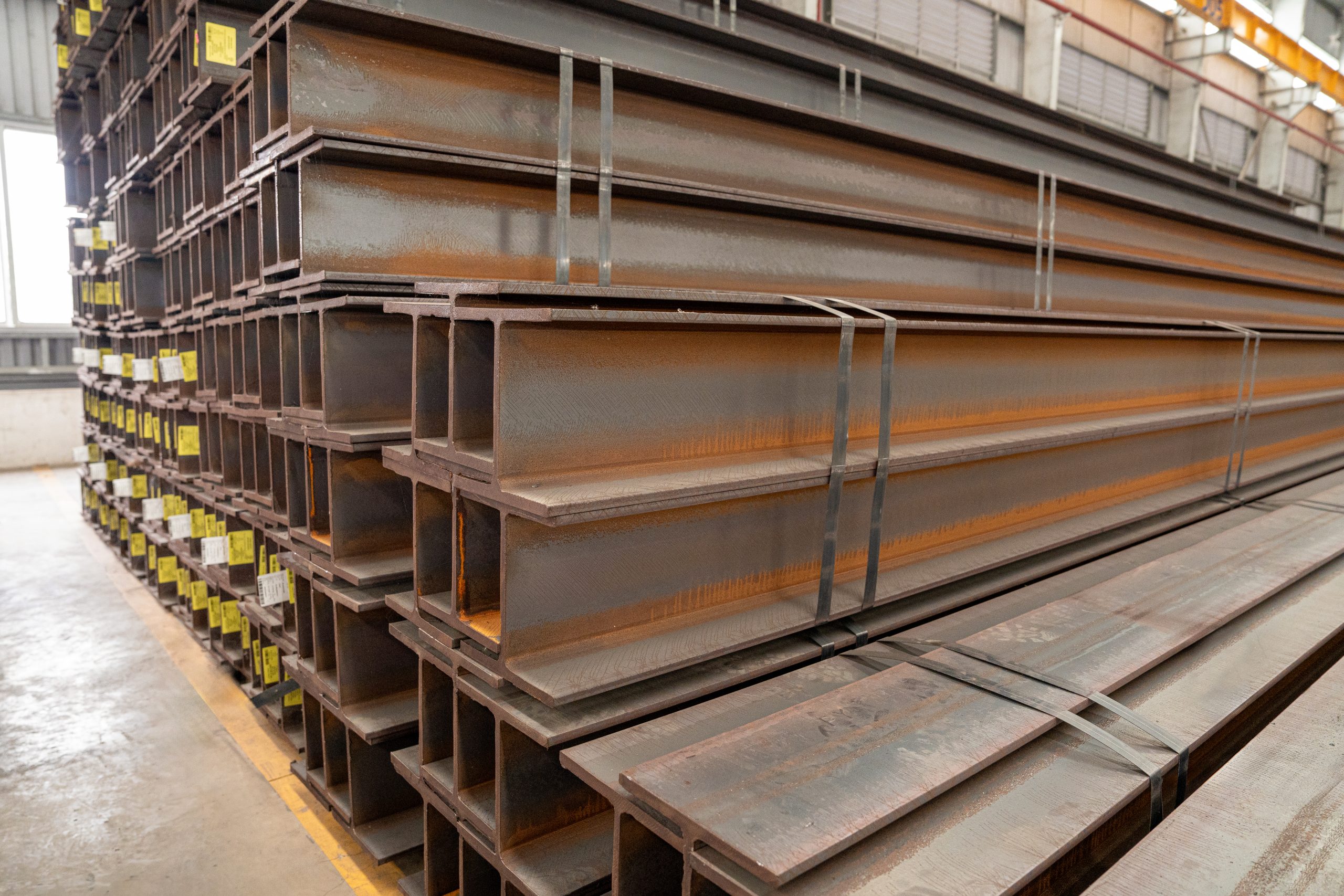

U Beam

U Beam

Size range:

U50 – U500

Thickness:

3.0 – 15.5mm

Length:

6,000 / 12,000mm or cut-to-size

Grades:

SS400, Q235B, S235JR, A36, A572, S355JR, SM490, etc

Mills:

VNO, An Khanh Steel, Posco Yamato Vina, JFE Steel, Hyundai Steel, Tanshang, etc

Standards:

JIS G3101:2015, GB/T 700-2006, EN 10025-2:2019, ASTM, JIS G3106, etc

Key advantages:

- High load-bearing capacity

- Durable structure with high rigidity

- Easy fabrication and assembly

- Wide range of applications

- Lighter weight compared to solid steel sections

- Easy maintenance and replacement

- Wide variety of steel grades and sizes

High production output

Large manufacturing capacity to efficiently fulfill bulk orders and key projects.

Competitive pricing

Offering budget-friendly yet competitive prices while maintaining product quality.

Trusted by clients

Chosen by hundreds of domestic and international clients for consistent quality and professional service.

Describe Product

Mục lục

Hot-rolled U-channel steel, also known as U Beam Steel, is a type of structural steel shaped like the letter “U”, featuring two parallel flanges connected by a central belly. This steel type is well known for its excellent load-bearing capacity, high rigidity, and wide applicability in construction and industrial fields.

I. FEATURES

- High load-bearing capacity: U-channel steel has a U-shaped cross-section that provides good resistance to compression and lateral bending, making it especially effective as support beams, frames, or auxiliary structural components.

- Durable structure with high rigidity: With thick flanges and strong structural integrity, U-beams offer long-lasting performance and are less prone to deformation under mechanical stress.

- Easy of fabrication and assembly: Easily cut, welded, drilled, and connected with other materials, U-channel steel is convenient for on-site fabrication and installation.

- Wide range of applications: Widely used in civil and industrial construction, workshops, mechanical fabrication, vehicle frames, gates, elevators, scaffolding, and more.

- Lighter weight compared to solid steel sections: Reduces overall structural load, helping to lower foundation and transportation costs.

- Easy maintenance and replacement: Its simple structure makes inspection and replacement easy—ideal for projects that require regular maintenance or upgrades.

- Various production standards: Can be manufactured according to JIS, ASTM, TCVN, and other standards, with various steel grades and dimensions to meet specific technical requirements.

| Tính chất vật lý(Mechanical Properties) | Tính chất hoá học(Chemical Composition) | |||||||

|---|---|---|---|---|---|---|---|---|

| Mác thép(Grade) | Độ bền chảy(Yeild Strength) (Mpa ~ N/mm2) Min |

Độ bền kéo(Tensile Strength) (Mpa ~ N/mm2) Min |

Độ giãn dài(Elongation) % |

C% | Si% | Mn% | P% | S% |

| SS400 | ≥ 245* | 400 – 510 | ≥ 21 | ≤ 0.29 | ≤ 0.40 | ≤ 1.60 | ≤ 0.050 | ≤ 0.050 |

| Q235B | ≥ 235* | 375 – 500 | ≥ 26* | ≤ 0.20 | ≤ 0.30 | 0.30 – 0.70 | ≤ 0.045 | ≤ 0.045 |

| S235JR | ≥ 235* | 360 – 510 | ≥ 26* | ≤ 0.17 | ≤ 0.35 | ≤ 1.40 | ≤ 0.035 | ≤ 0.035 |

| A36 | ≥ 250 | 400 – 550 | ≥ 20 | ≤ 0.26 | ≤ 0.40 | ≤ 0.040 | ≤ 0.050 | |

| A572 Gr 50 | ≥ 345 | 450 – 620 | ≥ 18 | ≤ 0.23 | ≤ 0.40 | ≤ 1.35 | ≤ 0.030 | ≤ 0.030 |

| S355JR | ≥ 355* | 470 – 630 | ≥ 20 | ≤ 0.22 | ≤ 0.55 | ≤ 1.60 | ≤ 0.035 | ≤ 0.035 |

| SM490 | ≥ 325 | 490 – 610 | ≥ 19 | ≤ 0.18 | ≤ 0.55 | ≤ 1.40 | ≤ 0.030* | ≤ 0.030* |

II. TOLERANCE

Thickness tolerance: ± 0.7 – 1.0mm

Height & flange length tolerance: ± 1.5 – 3.0mm

Length tolerance: + 40mm

Weight tolerance: ±05 – 07%

III. PACKAGING

Bundle weight: 2.5 – 3.0 tons per bundle

IV. PRACTICAL APPLICATIONS

- Pre-engineered steel building frames and factory structures

- Load-bearing beams in high-rise buildings

- Bridge frameworks, piers, and support foundations

- Design of scaffolding structures and lifting gantries

- Industrial equipment and heavy machinery

- Manufacturing of trucks, ships, and containers

V. U CHANNEL BRANDS

Currently, there are several well-known and reputable U channel brands on the market, including: An Khanh Steel, Vinaone, A Chau Steel, Nippon Steel, Hyundai Steel, Tangshan.

Angle Steel

Angle Steel U Beam

U Beam H Beam

H Beam I-BEAM

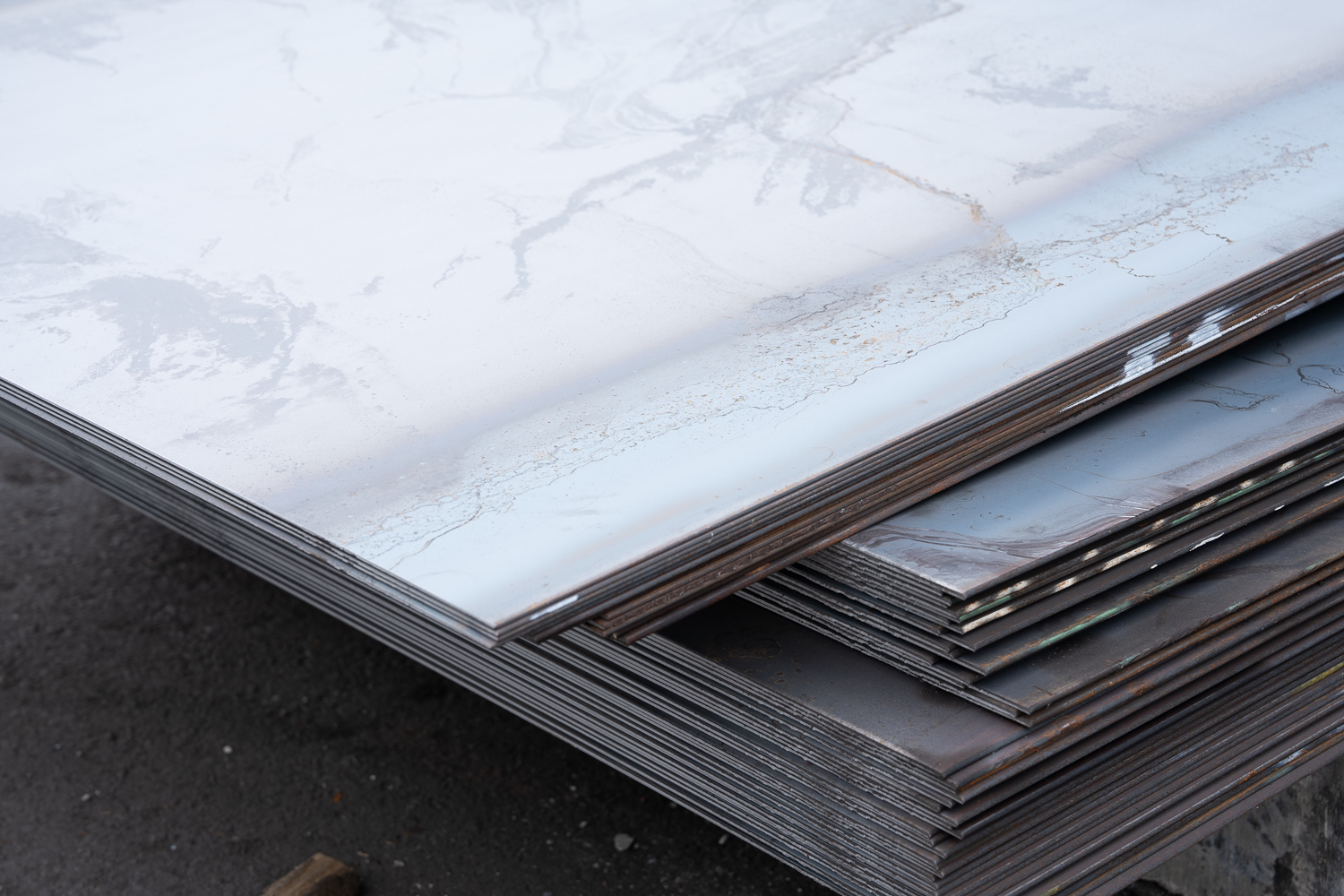

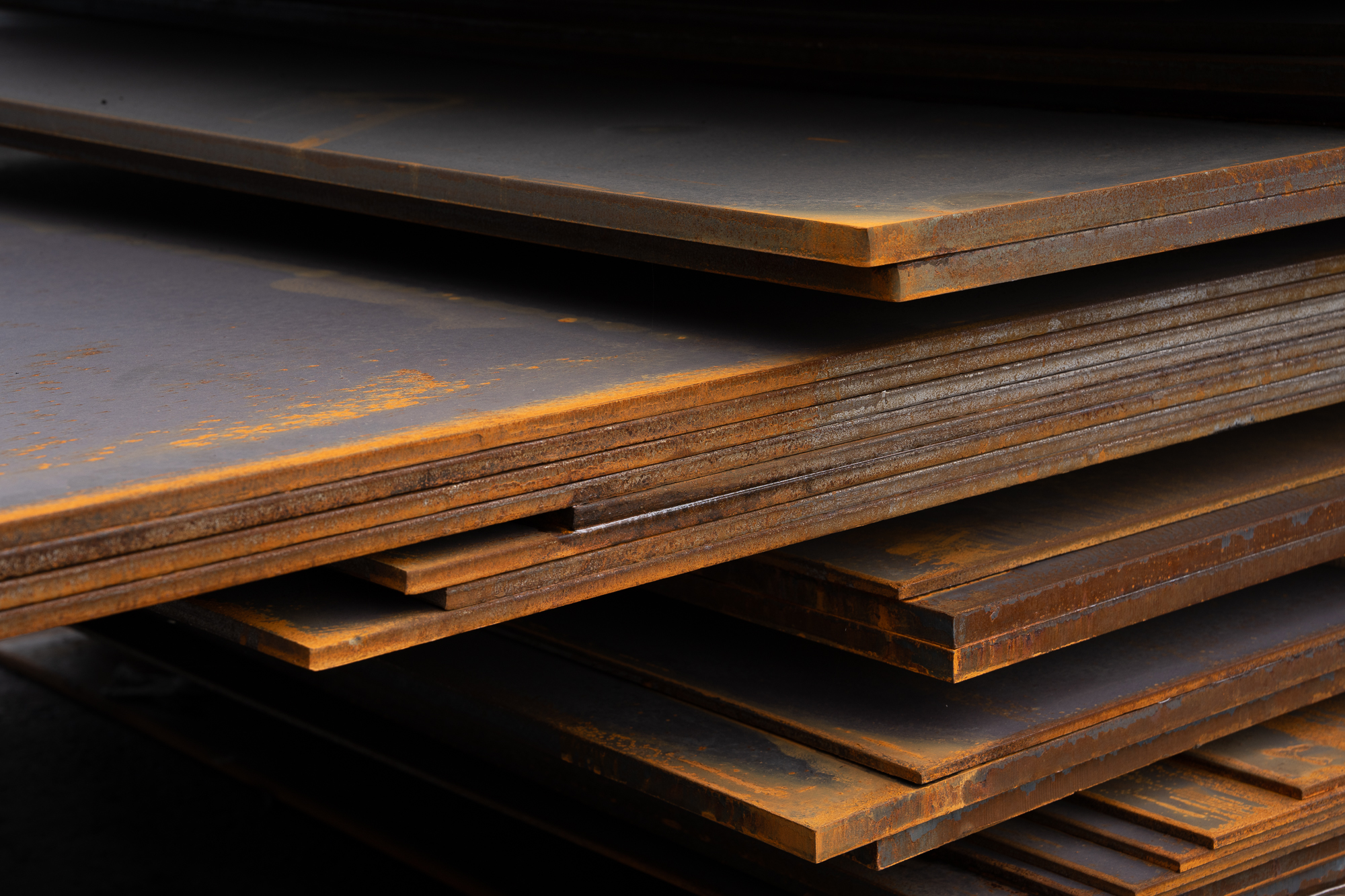

I-BEAM Steel Plate

Steel Plate Steel Sheet

Steel Sheet High Strength Steel Plate

High Strength Steel Plate Special Steel Plate

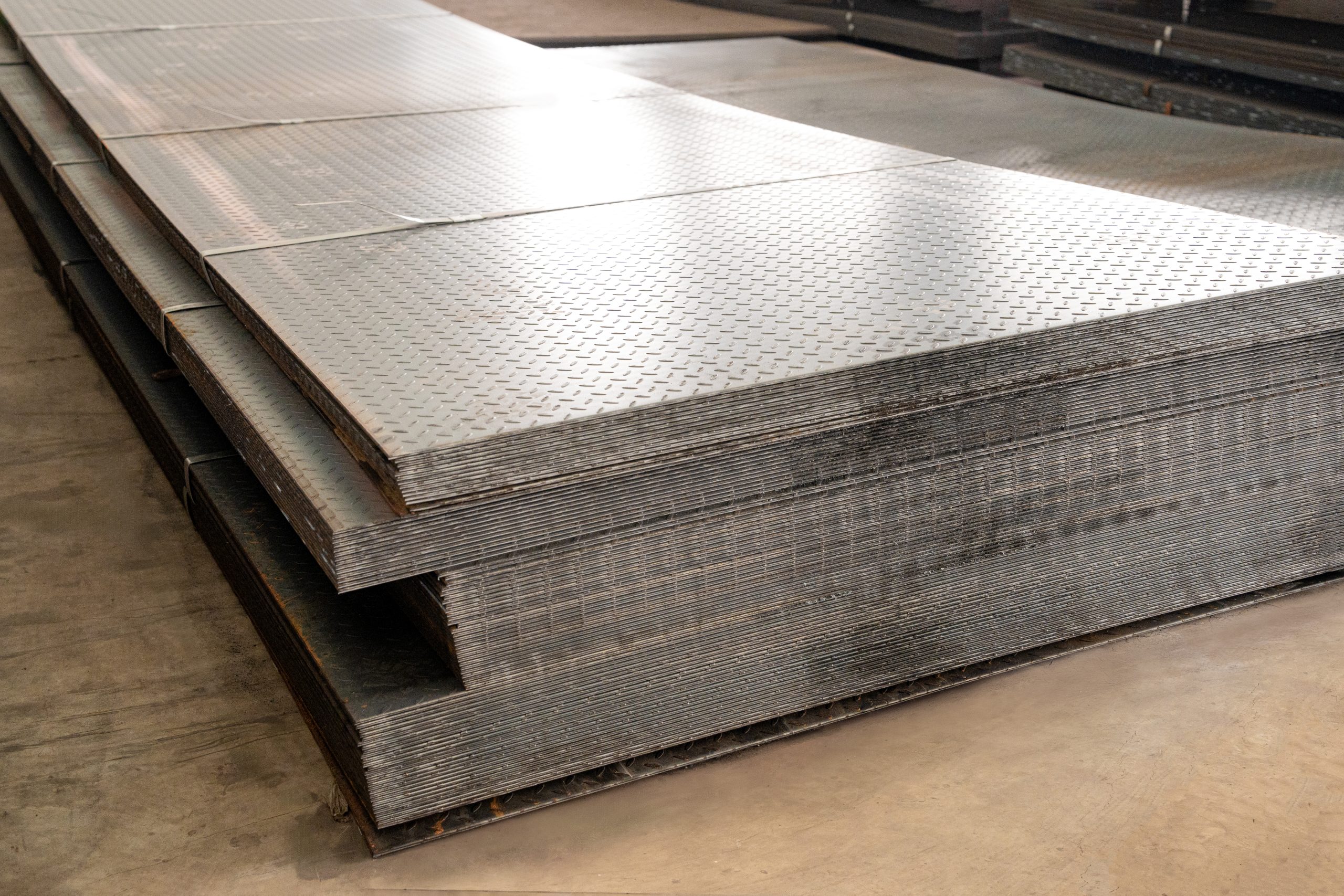

Special Steel Plate Checkered Steel Plate

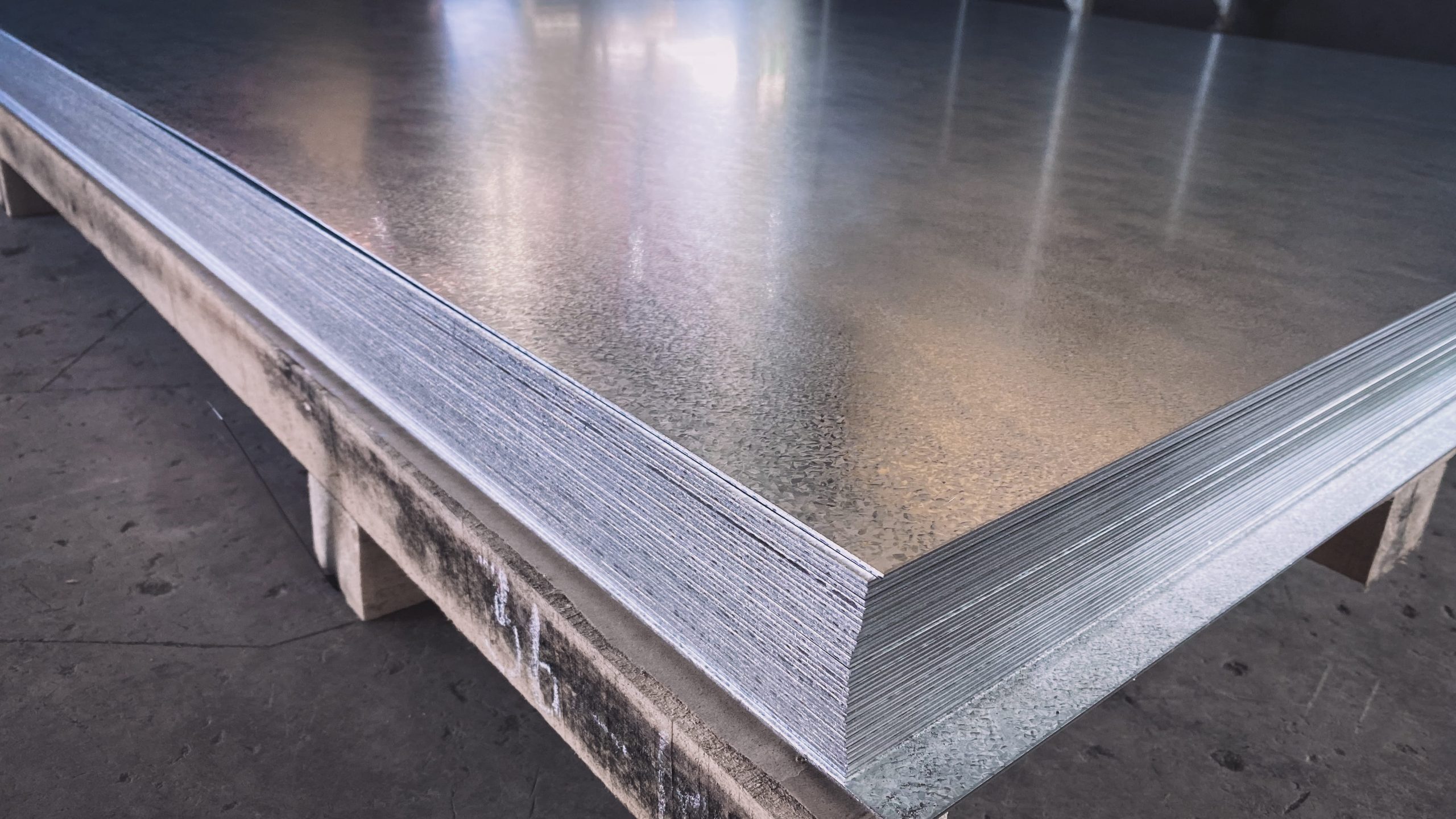

Checkered Steel Plate Galvanized Steel Sheet

Galvanized Steel Sheet Hot Rolled Coil

Hot Rolled Coil Cold Rolled Coil

Cold Rolled Coil Galvanized Coil

Galvanized Coil Steel Strip

Steel Strip Square Bar

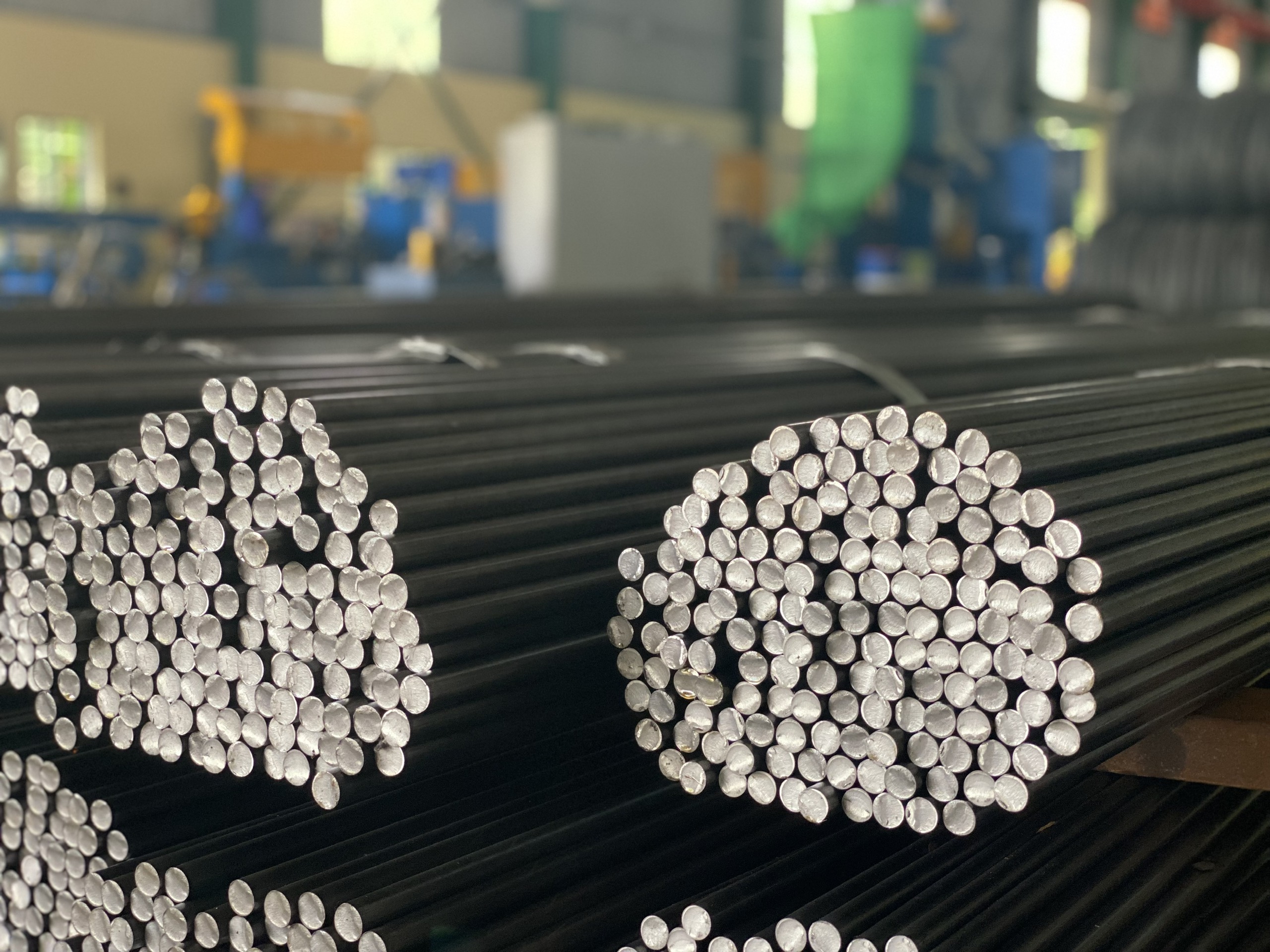

Square Bar Round Bar

Round Bar WELDED PIPE

WELDED PIPE Seamless Steel Pipe

Seamless Steel Pipe Steel tube

Steel tube Square Tube

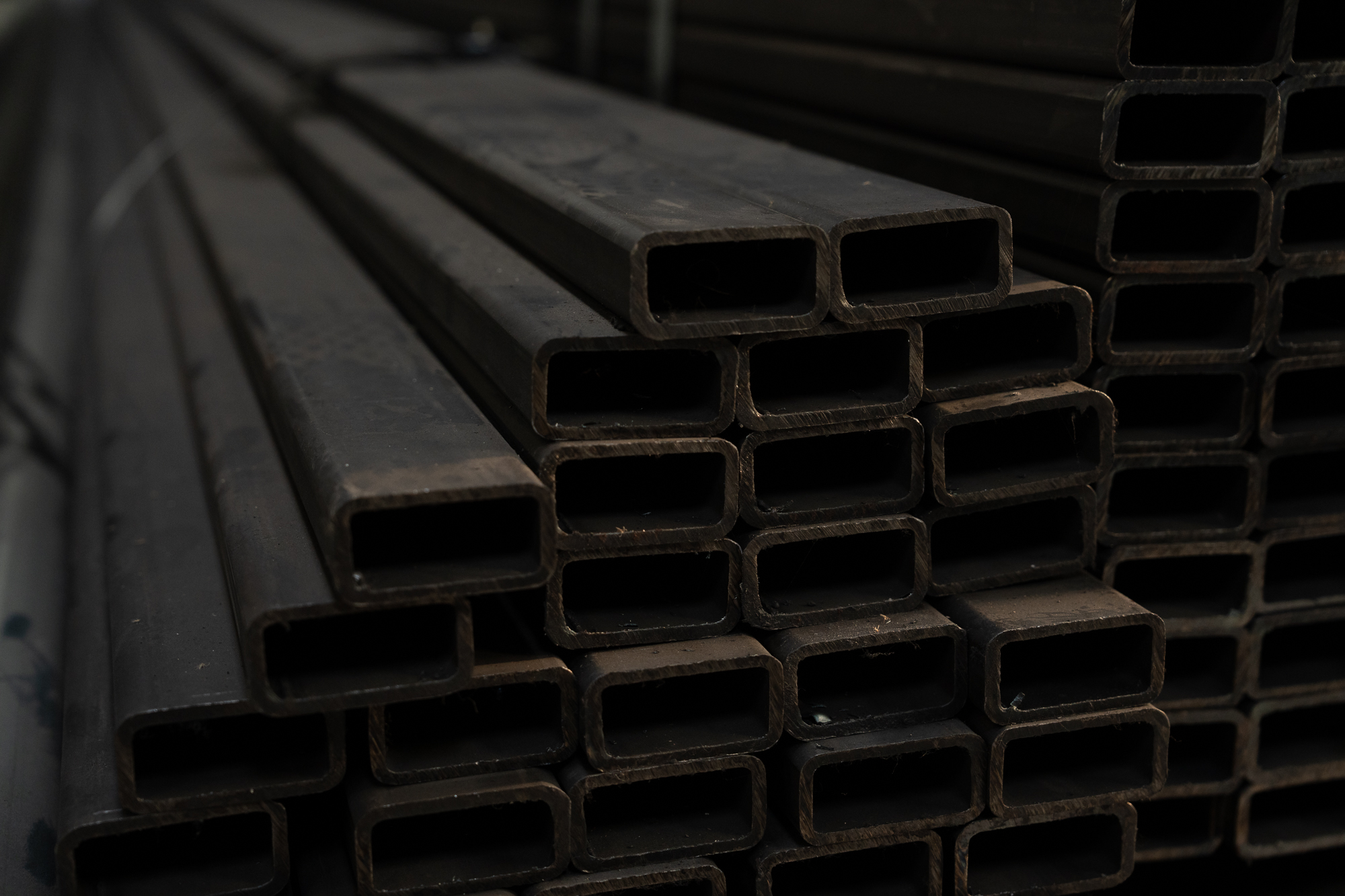

Square Tube Rectangular Tube

Rectangular Tube Wire Rod

Wire Rod Deformed Bar

Deformed Bar Steel Sheet Pile

Steel Sheet Pile Steel Purlin

Steel Purlin Steel Rail

Steel Rail Steel Fittings

Steel Fittings Stainless Steel

Stainless Steel Steel Fabrication

Steel Fabrication